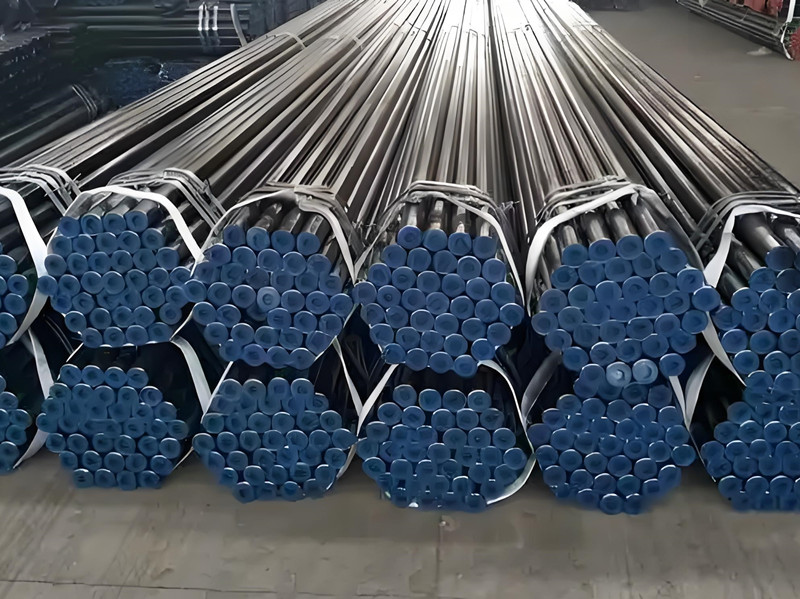

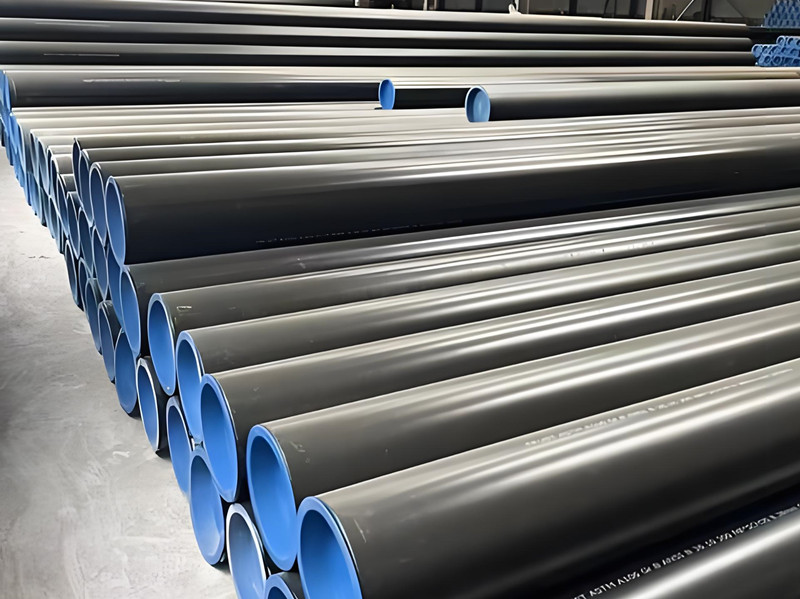

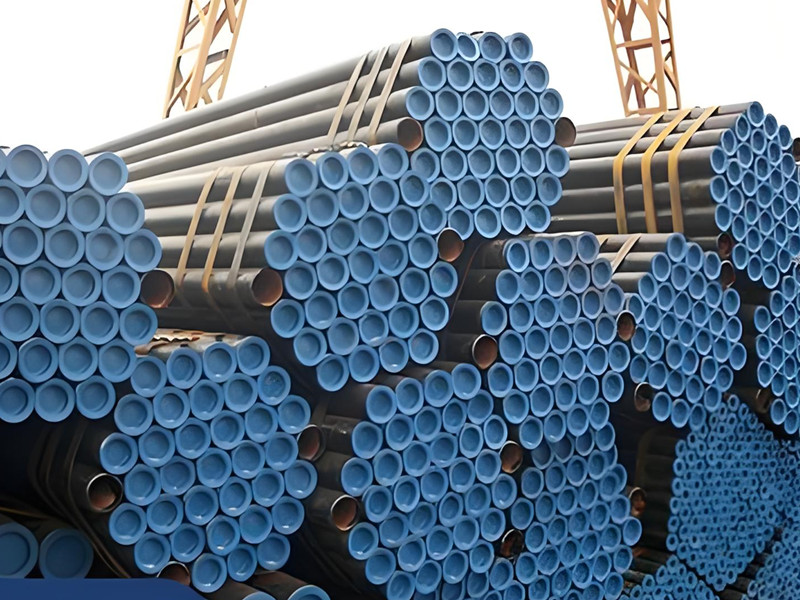

What is seamless line pipe?

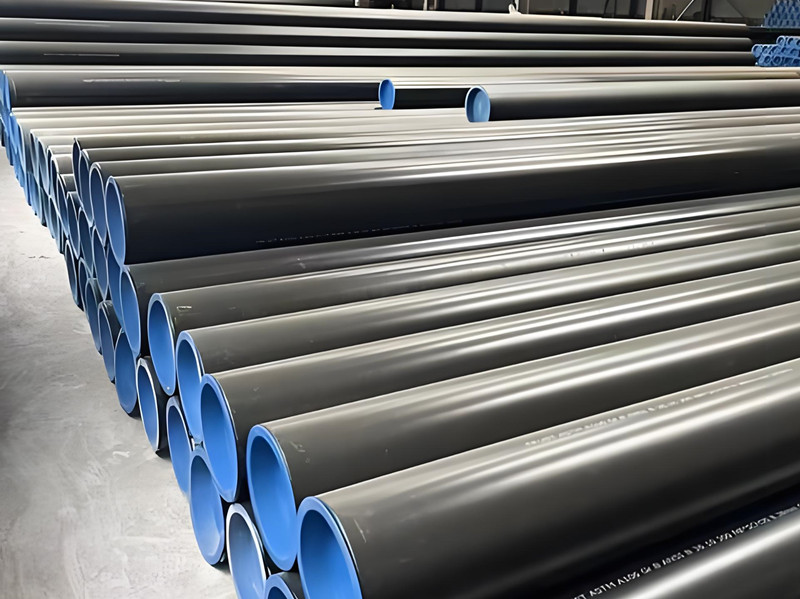

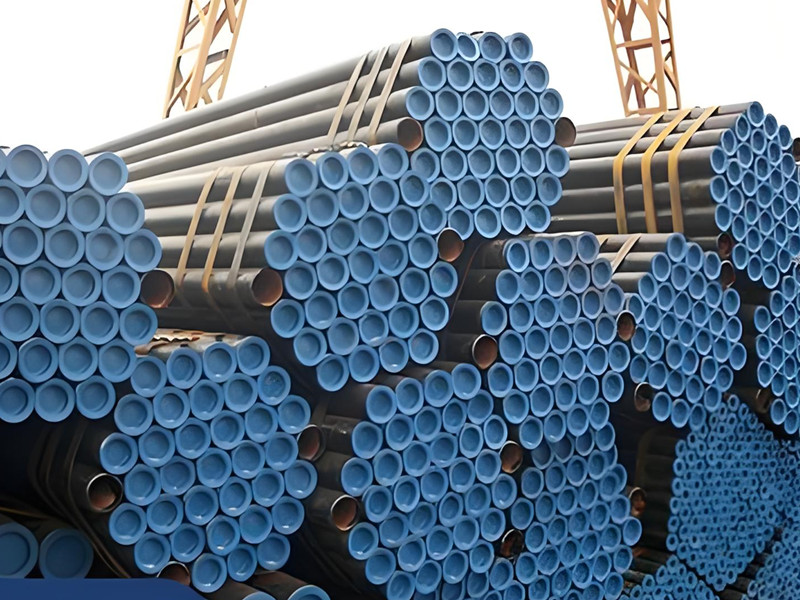

Seamless line pipe is a long, hollow steel strip with no welds. It is made by perforating a single piece of round steel or by hot rolling or cold drawing. The seamless line pipe body has no spiral or straight welded joints. It features uniform wall thickness, dense structure, high pressure resistance, and excellent toughness.

It is specifically used in pipeline systems for transporting fluids such as oil, natural gas, water, and steam. It is a key material in long-distance oil and gas pipelines, high-pressure gathering stations, refineries, boilers, and petrochemical heat exchange equipment.

Applications of Seamless Line Pipe

1. High-Pressure Oil and Gas Transportation

Environment: Long-distance oil and gas pipelines on land and undersea.

Reason: The internal pressures of these pipelines are extremely high, and the media they transport (crude oil and natural gas) are flammable and explosive. Seamless pipes lack the potential weak points of welds, allowing them to withstand extremely high pressures (often higher than LSAW pipes), thus avoiding leaks or explosions caused by weld defects and providing the highest level of safety.

2. Highly Corrosive Environments

Environment: Transporting oil or natural gas containing highly corrosive components such as high levels of hydrogen sulfide (H₂S), carbon dioxide (CO₂), and chloride ions (commonly known as "sour oil" or "sour gas").

Reason: Seamless pipes can undergo heat treatment processes such as through-hardening and tempering, resulting in highly uniform metallurgical structure and mechanical properties (especially corrosion resistance) throughout the pipe. In contrast, the weld area of seamed pipes differs from the parent material in chemical composition and metallurgical structure, making them more susceptible to corrosion in corrosive media and leading to corrosion perforation or stress corrosion cracking.

3. Extreme Geographic and Climatic Environments

Environment: Extremely cold polar regions, deep ocean, seismic zones, geologically unstable areas, etc.

Reason: These environments place extremely stringent demands on the low-temperature toughness, fatigue resistance, pressure-bearing capacity, and overall reliability of pipe materials. Seamless pipes offer superior isotropy and more stable performance under complex stresses, making them the preferred choice for these critical locations.

4. Power Plant Boiler Systems

Environment: Boiler superheaters, reheaters, and main steam lines in thermal and nuclear power plants.

Reason: These pipes operate under high temperatures (up to 600°C) and high pressures for extended periods, placing extremely high demands on the material's creep strength, endurance strength, and oxidation resistance. The uniform microstructure of seamless pipes ensures stable performance at high temperatures, reducing the risk of weld failure from prolonged high-temperature exposure.

5. Chemical and Petrochemical Plants

Environment: Reactors, heat exchangers, and high-temperature and high-pressure process piping in refineries and chemical plants. Reason: Transporting high-temperature, high-pressure, and often corrosive chemical media (such as hydrogen, ammonia, urea, and hydrocarbons). This also requires uniform mechanical properties and corrosion resistance.

6. Food and Pharmaceutical Industries

Environment: Piping systems for transporting dairy products, beverages, beer, and pharmaceutical raw materials.

Reason: While welded stainless steel pipe is also common, for applications requiring the highest levels of hygiene (such as SIP/CIP cleaning and sterilization), seamless stainless steel pipe offers a smooth inner wall with no weld indentations, making it easier to clean and sterilize. This eliminates dead corners and reduces the risk of microbial growth and contamination.

EN

EN