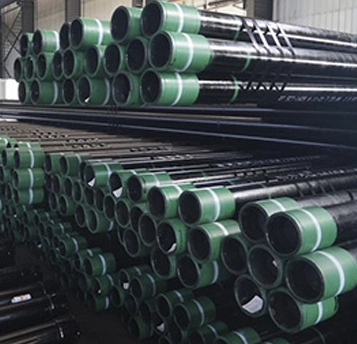

API 5CT Standard Seamless Steel Pipes, known as high-quality api 5ct seamless pipe, are high-performance pipes designed for use in oil and gas well drilling and extraction. Manufactured to meet the American Petroleum Institute (API) 5CT specification, these api 5ct seamless pipe are used as casing and tubing to support well structures and transport oil, gas, and other fluids.

They are available in various grades, such as J55, K55, N80, and P110, to suit different well conditions, including high pressure, temperature, and corrosive environments—all grades fully adhering to api 5ct standard requirements. Their seamless construction ensures superior strength, durability, and resistance to wear, making api 5ct casing and api 5ct tubing essential for reliable and safe operations in both onshore and offshore drilling applications.

EN

EN