About Cangzhou Silver Valley

Cangzhou Silver Valley Technology CO., LTD is located in Lijiapu Industry, known as the"Capital of Pipe Fittings in China". It is a comprehensive enterprise integrating research and development, pro-duction, sales, quality inspection, packaging, and trans- portation.

Our company mainly produces and exports steel pipes,flanges,and pipe fittings,which are widely used in shipbuilding,chemicals,oil,electricity,gas,water supply,and other fields.It has established long-term strategic cooperative relationships with many domestic and foreign companies.

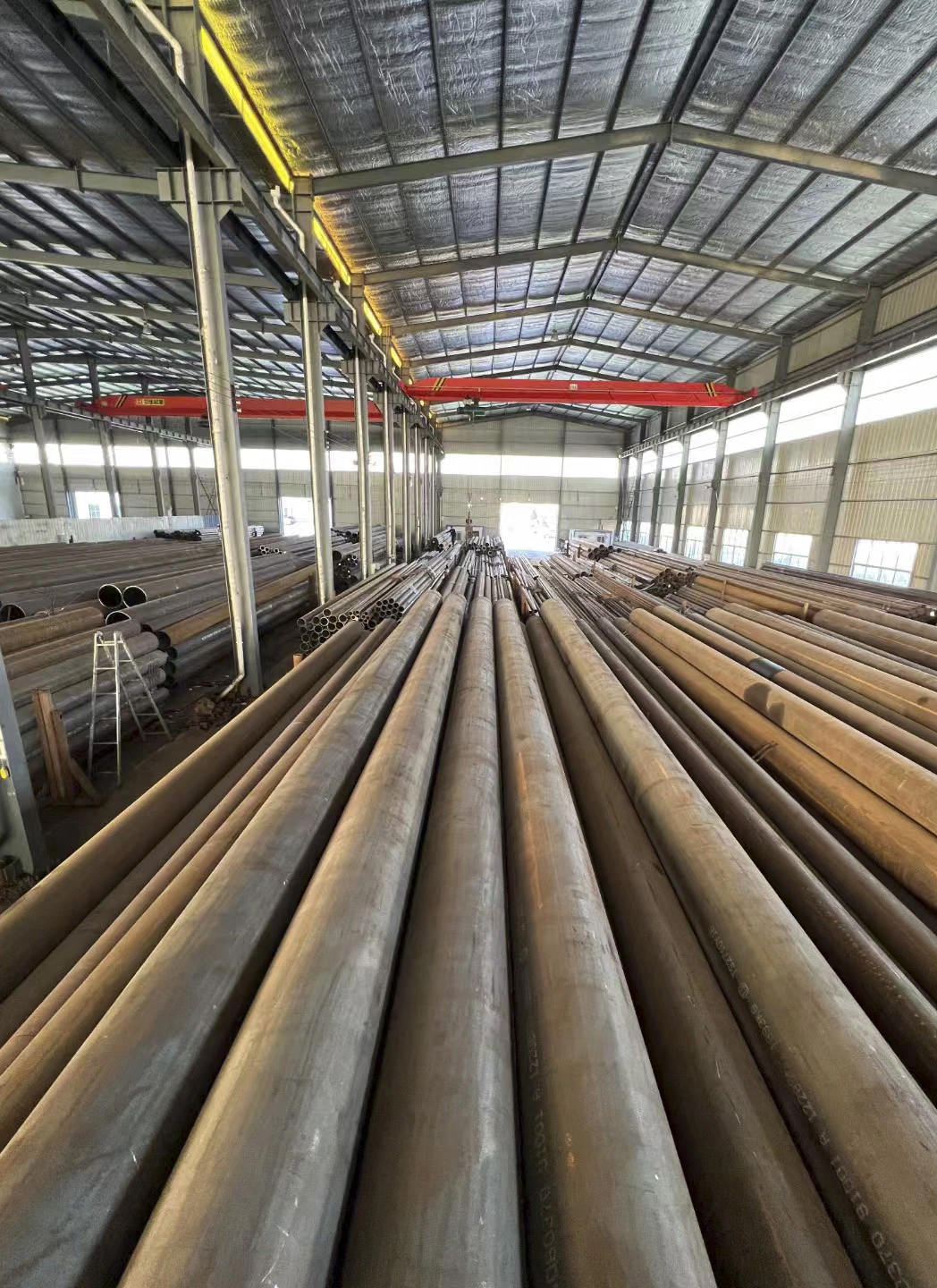

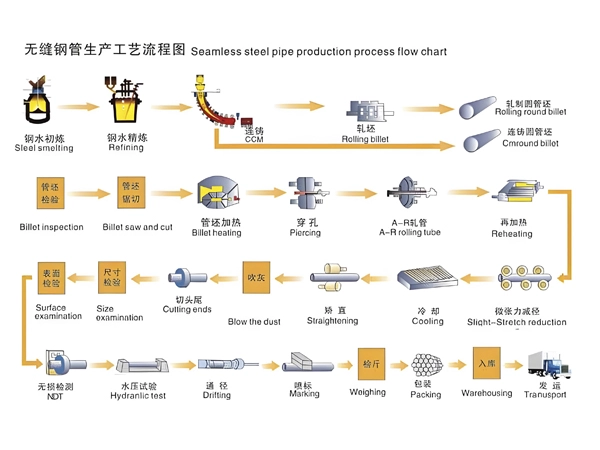

As one of the company's core products,steel pipes have a constant inventory of over 500,000 tons.The company produces various types of steel pipes,includ- ing seamless steel pipes,spiral steel pipes,and straight-seam steel pipes,to meet the needs of different customers.These products are strictly produced according to industry standards such as API5L, API5CT, ANSI, ASME, EN, DIN, GOST, JIS, KS, BS, ensuring that product quality meets customer require-ments.

EN

EN