Weld Neck Flange (WNF) and Slip-On Flange (SOF) are two common types of flanges in industrial piping systems, with significant differences in structure, strength, applications, and installation methods. Below is a comparison and selection guide between them:

Structural and Installation Comparison

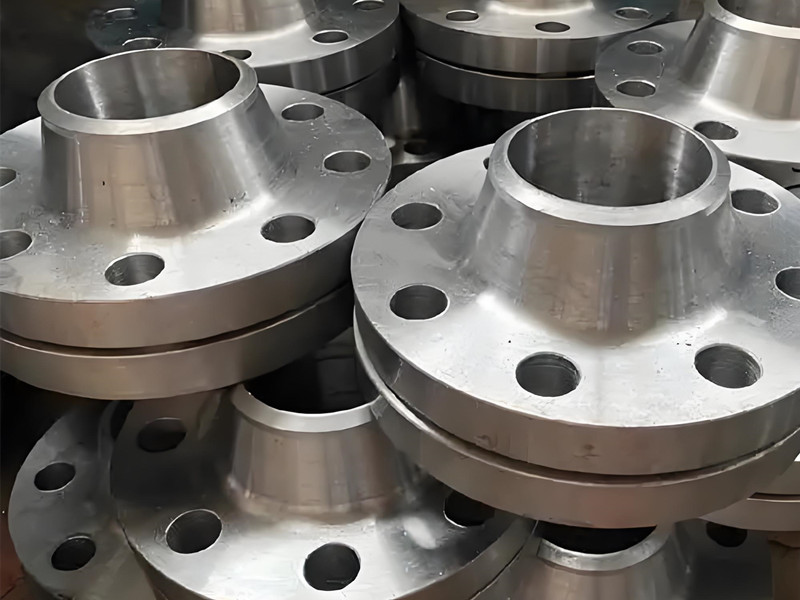

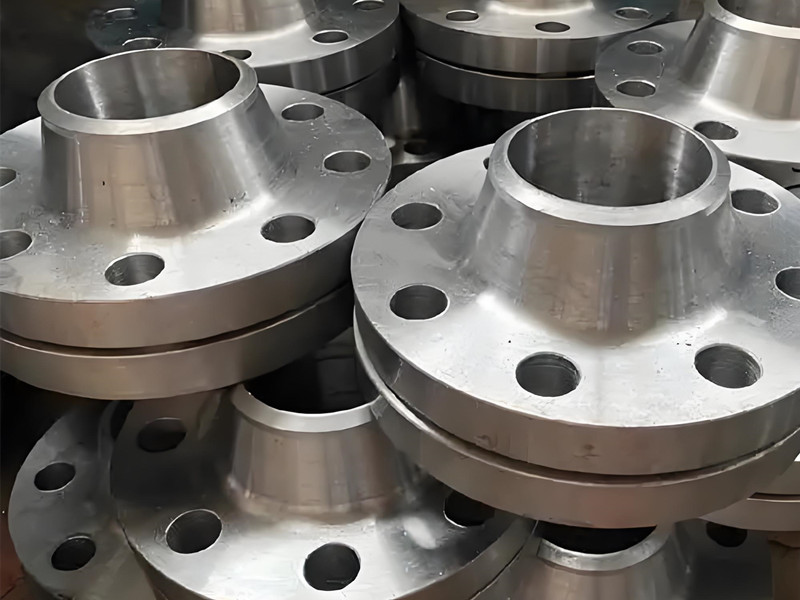

The Weld Neck Flange (WNF) connects to pipes via butt welding, featuring a tapered hub that ensures high strength and sealing integrity, though precise alignment is required during installation. In contrast, the Slip-On Flange (SOF) uses fillet welding, where the pipe slides through the flange and is welded on both the inside and outside, making it simpler to install but less robust structurally. The WNF consumes more material due to its hub design, making it ideal for critical high-pressure systems, while the SOF is lighter and more cost-effective, better suited for low-to-medium pressure applications.

Performance Comparison

The WNF excels in high-pressure, high-temperature, and high-vibration environments due to its even stress distribution, offering superior fatigue and impact resistance with minimal leakage risk—ideal for demanding industries like petrochemicals and power plants. The SOF, relying on fillet welds, has lower pressure and vibration resistance, making it suitable for low-to-medium pressure systems (e.g., water or air pipelines). The WNF’s welded construction, as perfected by leading weld neck flanges manufacturers, ensures long-term reliability, while the SOF provides cost efficiency for non-critical applications. For corrosive or hazardous media, the WNF is the safer choice, whereas the SOF is preferable for budget-conscious projects requiring easy maintenance.

How to Choose?

Opt for WNF in high-pressure/high-temperature (e.g., oil pipelines), high-vibration (e.g., pump/compressor outlets), hazardous media (toxic/flammable fluids), or long-term reliability (e.g., nuclear/deep-sea pipelines). Choose SOF for low-pressure/low-temperature systems (e.g., water/air), tight budgets, space constraints, or quick installations (e.g., HVAC). Economically, the WNF has higher upfront costs but lower maintenance, while the SOF is cheaper but may need more frequent inspections. The final decision should balance operating pressure, media properties, budget, and installation requirements.

EN

EN