Seamless steel pipes play a critical role in the oil and gas industry, offering superior performance that makes them essential for exploration, extraction, transportation, and processing. Below are their key applications and functions:

Oil and Gas Drilling (Upstream Sector)

Drill Pipes and Drill Collars

Seamless steel pipes are used to manufacture high-strength drill pipes and collars, which withstand high torque, extreme pressure, and complex geological stresses during drilling, ensuring efficiency in deep and ultra-deep well operations. The reliability of oil and gas seamless steel pipe is critical for these demanding applications.

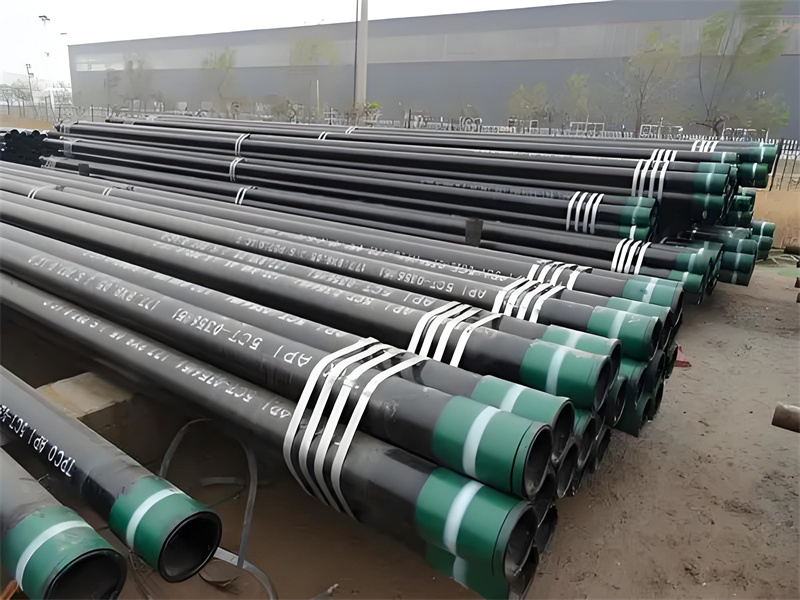

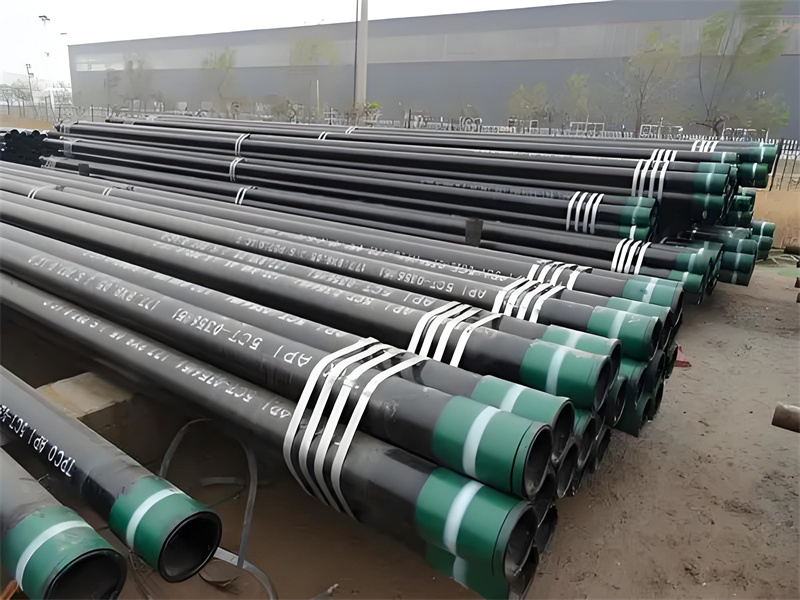

Casing and Tubing

Casing: Supports wellbore walls, prevents collapse, and isolates different formations (e.g., oil/gas zones, water layers).

Tubing: Transports oil and gas from the well bottom to the surface, requiring high-pressure and corrosion resistance (e.g., against H₂S, CO₂ in sour environments).

Common Materials: API-grade steels (J55, N80, P110) or specialty alloys (e.g., 13Cr, duplex stainless steel).

Coiled Tubing

Used in well intervention, acidizing, and fracturing operations, offering flexibility and high strength for repeated spooling.

Oil and Gas Transportation (Midstream Sector)

Long-Distance Pipelines

Seamless pipes are preferred for high-pressure trunk lines or critical sections (e.g., river crossings, seismic zones) due to their lack of weld seams, reducing failure risks.

Onshore/submarine long-distance pipelines: transport crude oil and natural gas from production areas to refineries or city gate stations. Submarine pipelines must also withstand external water pressure, ocean current shock, and low-temperature embrittlement. They generally comply with API 5L standards, with steel grades ranging from B to X80, X100, and even X120. They also feature 3PE/FBE anti-corrosion coatings or composite pipe structures.

Processing and Storage (Downstream Sector)

Refining Equipment

Used in high-temperature, high-pressure reactors and heat exchangers (e.g., hydrocracking units), often made of corrosion-resistant alloys (e.g., Cr-Mo steel).

LNG Equipment

Cryogenic seamless pipes (-196°C) for liquefied natural gas storage and transfer, typically made of 9% nickel steel or austenitic stainless steel.

Special Applications

Deepwater Oil & Gas Fields

Require seamless pipes with high external pressure resistance and seawater corrosion resistance (e.g., thick-walled, duplex stainless steel).

Shale Gas/Tight Oil Development

High-pressure fracturing pipelines must endure extreme cyclic stresses (e.g., Q125 grade).

Advantages of Seamless Steel Pipes

High Strength & Reliability: No welded seams, ideal for high-pressure and fatigue-load environments.

Corrosion Resistance: Customizable via alloying (e.g., Cr, Mo, Ni) for sour or marine conditions.

Precision Dimensions: Ensures leak-proof connections, minimizing spill risks.

Industry Standards

API Standards: API 5CT (casing/tubing), API 5L (line pipe).

International Standards: ISO 11960, ASTM A106/A333, etc.

EN

EN