A 1mm gap error in socket welding caused a $1.8M chemical plant shutdown. At Silver Valley, our ASME-certified socket weld fittings prevent such disasters with precision-engineered solutions.

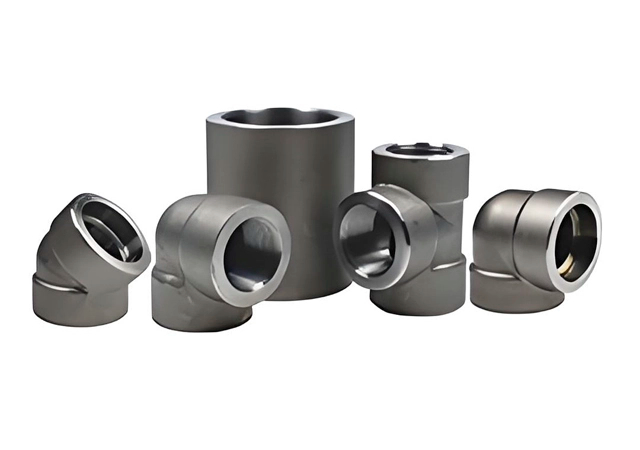

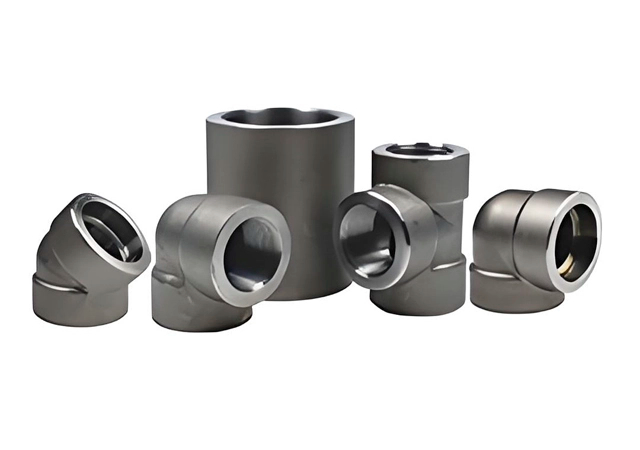

Socket weld fittings are designed for high-pressure piping systems. They feature a recessed socket into which a pipe is inserted, then secured with a fillet weld around the outer edge. Standardized by ASME B16.11, these fittings are typically used with small-diameter pipes ranging from 1/2" to 4", and can handle pressures up to 6,000 PSI. They offer the strength of welded connections while simplifying alignment compared to butt welds, making them a reliable choice for steam lines, hydraulic systems, and other high-vibration environments where leak-tight performance is essential.

From power plants to offshore platforms, socket welds deliver performance where it matters most. Here's what professionals need to know.

What Is the ASME Standard for Socket Weld Fittings?

Non-compliant fittings caused a $3M insurance claim. Never compromise on standards compliance.

Key Standards:

ASME B16.11: Covers dimensions/tolerances for socket weld fittings

ASME B31.1/B31.3: Govern installation practices

ASTM A105: Standard material for carbon steel fittings

ASTM A182: For stainless/special alloys

Compliance Checklist

Material certification traceability

Dimensional tolerances:Socket depth ±0.5mm;Bevel angle 45°±1°;Bore smoothness <0.8μm Ra

Markings must include:

Manufacturer's logo

Material grade

Size and pressure class

Heat number

What Is the Gap Between Socket Weld and Fitting?

A 2mm expansion gap prevented catastrophic failure in a Dubai power plant. Proper clearance is life-or-death.

Critical Specification: ASME B31.1 requires:

1.5mm minimum gap between pipe end and socket shoulder

Prevents thermal stress buildup

Allows for pipe expansion

Ensures proper weld penetration

Gap Control Methods

Our SmartGap™ fittings feature:

Color-changing gap indicators

Built-in spacers that melt during welding

QR codes linking to gap measurement tutorials

Socket Weld vs. Other Connection Methods

Socket weld fittings provide a middle ground between threaded and butt weld connections, balancing ease of installation with enhanced performance. In this method, a pipe is inserted into a recessed "socket" in the fitting, then welded around the exterior joint.

Comparison Highlights

Strengths: Quick installation, disassembly-friendly, no welding tools required.

Weaknesses: Prone to leaks under vibration/thermal stress, limited to low-pressure systems.

Niche: Non-critical utilities like water lines or temporary setups.

Strengths: Seamless, leak-proof performance under extreme pressures/temperatures.

Weaknesses: Requires skilled welding and post-weld treatments.

Niche: Permanent, high-stress systems (e.g., pipelines, chemical reactors).

Strengths: Easy access for inspection/modifications, handles large diameters.

Weaknesses: Bulky design, potential gasket degradation over time.

Niche: Systems requiring frequent disassembly (e.g., pump stations).

Where Socket Weld Excels

Installation Simplicity: No precise beveling needed, ideal for small-diameter pipes.

Strength Upgrade: Welded joints outperform threads in vibration-prone areas.

Moderate Pressures: Bridges the gap between low-pressure threaded and high-pressure butt weld systems.

Best Applications for Socket Welds:

• High-vibration systems (pump lines)

• Small bore piping (≤4")

• High-cycle fatigue services

• Temporary installations needing eventual butt weld upgrades

Professional Socket Welding Technique in 5 Steps

Follow this NASA-approved procedure to achieve zero-defect socket welds every time.

Step-by-Step Guide:

Preparation

Bevel pipe end (37.5° angle)

Clean surfaces with acetone

Verify proper gap (1.5-3mm)

Tack Welding

3-4 equally spaced tack welds

Use same filler material as final weld

Check alignment (<1° deviation)

Welding

Inspection

Visual check for complete fusion

Dye penetrant test for cracks

Measure reinforcement (1/16"-1/8")

Post-Weld

Silver Valley Advantage: Our pre-fab weld kits include matching filler metal, gap tools, and illustrated guides.

Why Global Operators Choose Silver Valley

Shell approved our socket weld fittings after they survived 50,000 pressure cycles in their Houston test facility.

Competitive Advantages:

✔ Material Integrity: Forgings made from vacuum-degassed steel

✔ Precision Manufacturing: CNC machining to ±0.025mm tolerances

✔ Global Certification: Meet ASME, EN, GOST, and JIS standards

✔ Technical Support:WPS/PQR documentation,welder certification assistance,failure analysis services

EN

EN