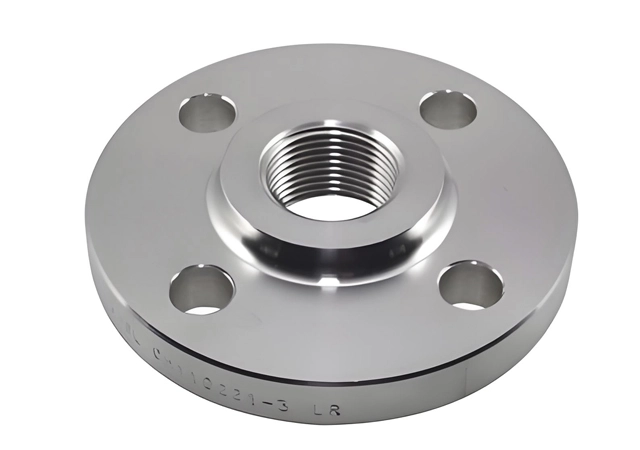

What is Threaded Flange

A threaded flange is a type of flange that uses threads to connect to pipes or other components. It has internal or external threads that match the corresponding threads on the pipe ends, with the female threaded flange being a typical internal-threaded variant for precise connection needs.

The main function of threaded flanges is to provide a convenient and reliable connection method in piping systems. They are easy to install and disassemble without the need for welding, which reduces installation time and cost. Among the material options, steel threaded flange and threaded steel flange are favored for general industrial use due to their durability and cost-effectiveness, while ss threaded flange (stainless steel grade) and stainless threaded flange stand out in corrosion-prone environments like chemical or marine applications.

They are suitable for low-pressure and low-temperature applications, such as in some water supply, gas supply, and small-scale chemical piping systems. In addition, they can help to isolate and connect different parts of the pipeline system, facilitating maintenance and system expansion.

Types of Threaded Flange

Standard Threaded Flange: Used in general low-pressure applications.

Reducing Threaded Flange: Connects pipes of different diameters.

Raised Face (RF) Threaded Flange: Features a raised face to improve sealing with a gasket.

Flat Face (FF) Threaded Flange: Has a flat face for mating with flat-faced equipment.

Ring-Type Joint (RTJ) Threaded Flange: Used in high-pressure applications with a metal ring gasket.

Sizes and Pressure Ratings of Threaded Flange

Sizes:

ASME B16.5 Threaded Flanges:

Sizes: 1/2 inch (15 mm) to 24 inches (600 mm).

Commonly used sizes: 1/2", 3/4", 1", 2", 4", 6", 8", 10", 12", 14", 16", 18", 20", 24".

ASME B16.47 Threaded Flanges:

Sizes: 26 inches (650 mm) to 60 inches (1500 mm) (for larger-diameter applications).

EN 1092-1 Threaded Flanges:

Sizes: DN10 (10 mm) to DN600 (600 mm).

pressure ratings:

ASME B16.5 Pressure Classes:

Class 150: Suitable for low-pressure applications.

Class 300: Medium-pressure applications.

Class 600: Higher-pressure applications.

Class 900: High-pressure systems.

Class 1500: Very high-pressure systems.

Class 2500: Extreme high-pressure systems.

EN 1092-1 Pressure Classes (PN Ratings):

PN6: 6 bar pressure rating.

PN10: 10 bar pressure rating.

PN16: 16 bar pressure rating.

PN25: 25 bar pressure rating.

PN40: 40 bar pressure rating.

Standards of Threaded Flange

ASME B16.5: It is an American standard that specifies dimensions, pressure ratings, and tolerances of threaded flanges. It classifies flanges into different pressure classes such as Class 150, Class 300, Class 600, etc. For example, in Class 150, a 1/2" threaded flange has an inside diameter of 0.93", an outside diameter of 3.50", and 4 bolt holes.

GB/T 9114-2010: It is a Chinese national standard. Under this standard, in the Steel Threaded Pipe Flanges with Neck, requirements are put forward for the type, parameters, technical conditions, etc. of threaded flanges. The pressure markings are divided into PN and Class markings, with PN having 12 pressure levels and Class having 6.

DIN Standards: In the German DIN standards, there are also relevant regulations for threaded flanges, covering aspects such as dimensions, materials, and manufacturing processes, which are widely used in the European market and some international projects.

Material Grade of Threaded Flange

Carbon Steel: ASTM A105, ASTM A350 LF2.

Stainless Steel: ASTM A182 F304/304L, F316/316L.

Alloy Steel: ASTM A182 F11, F22.

Nickel Alloys: Monel, Inconel, Hastelloy.

Applications of Threaded Flange

1. Petrochemical Industry

In the petrochemical industry, threaded flanges are often used to connect low-pressure pipes due to the risks of welding.

2. Water Treatment and Wastewater Management

Threaded flanges are easy to install and disassemble, and are suitable for pipe connections in water treatment plants and wastewater management systems.

3. Firefighting System

In firefighting systems, welding poses a safety hazard, and threaded flanges are a safe alternative.

4. Water Supply and Heating Systems

Threaded flanges are easy to install and maintain, and are commonly used in water supply and heating systems in residential and commercial buildings.

5. Low-pressure systems

Threaded flanges are suitable for low-pressure piping systems, such as water supply pipes and drainage systems.

EN

EN