Socket weld pipe reducer is a type of pipe fitting used to connect two pipes of different diameters in a piping system.

Unlike butt-weld reducers, which are welded directly to the pipe ends, socket weld reducers have a socket or recessed area that allows the pipe to be inserted into the fitting. The connection is then secured by fillet welding around the outer edge of the joint.

This type of fitting is commonly used in small-bore piping systems where high strength and leak-proof connections are required.

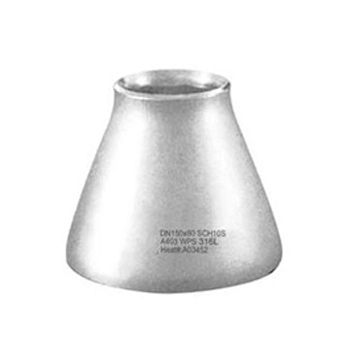

Concentric Reducers: These reducers have a symmetrical design with both ends aligned along the same centerline. They are used when the pipes need to maintain a consistent flow without any offset.

Eccentric Reducers: These reducers have one end offset from the centerline, creating a flat side. They are typically used in horizontal pipelines to prevent the accumulation of air or gases.

Design: Socket weld reducers have a socket or cavity on each end that fits the pipe.

They are available in concentric (aligned centerlines) and eccentric (offset centerlines) configurations.

Connection Method: The pipe is inserted into the socket, leaving a small gap (typically 1/16 inch) to allow for thermal expansion.

A fillet weld is applied around the outer edge of the joint to create a strong, leak-proof connection.

Sizes: Socket weld reducers are typically used for smaller pipe sizes, ranging from 1/8 inch to 4 inches in diameter.

Carbon Steel

Properties: High strength, cost-effective, suitable for high-pressure systems.

Stainless Steel

Properties: Excellent corrosion resistance, ideal for food processing and chemical industries.

Common Grades: SS304, SS316, SS304L, SS316L.

Alloy Steel

Properties: Enhanced resistance to heat and pressure, used in extreme environments.

Common Grades: WP11, WP22, WP91.

Duplex and Super Duplex Stainless Steel

Properties: High strength and excellent corrosion resistance, particularly in aggressive environments.

Common Grades: UNS S31803 (duplex), UNS S32750 (super duplex).

Oil and Gas: For small-bore piping in refineries and pipelines.

Chemical Processing: In corrosive or high-pressure environments.

Power Generation: For steam and water lines in power plants.

Pharmaceutical: In sanitary systems requiring clean and leak-proof connections.

Hydraulic Systems: For high-pressure fluid transport.

EN

EN