What is Socket Weld Pipe Fittings?

Socket weld pipe fittings are a type of pipe fitting used to connect pipes in high-pressure piping systems, including key components like socket weld pipe cap, socket weld eccentric reducer, and socket weld 90 elbow that fully adapt to high-pressure working requirements. They are designed with a socket or recessed area that allows the pipe to be inserted into the fitting, after which the joint is welded to create a strong, leak-proof connection. This type of fitting is commonly used in small-diameter piping systems where high strength and durability are required.

Materials and Standards of Socket Weld Pipe Fittings?

Socket weld fittings are typically made from materials like carbon steel, stainless steel, alloy steel, or duplex steel, depending on the application.

Carbon Steel Socket Weld Fittings

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Alloy Steel Forged Steel Socket Weld Fittings

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Stainless Steel Socket Weld Fittings

ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321, F309, F347, F904L

Duplex Steel SW Pipe Fittings

ASTM A182 F51, F53, F55, F56, F57, F60

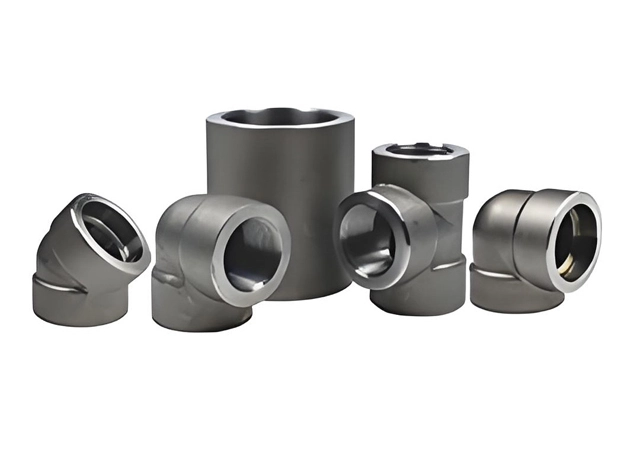

Type of Socket Weld Pipe Fittings?

1. Socket Weld Elbow

Function: Used to change the direction of the pipeline.

Common Angles: 90° and 45° elbows.

Application: Redirects flow in high-pressure systems.

2. Socket Weld Tee

Function: Allows for branching of the pipeline into two directions.

Equal Tee: All three openings are the same size.

Reducing Tee: One opening is smaller than the other two.

Application: Used to split or combine flow in piping systems.

3. Socket Weld Coupling

Function: Connects two pipes of the same diameter in a straight line.

Full Coupling: Connects two pipes end-to-end.

Half Coupling: Used for branching or connecting to smaller pipes.

Application: Joins pipes in high-pressure systems.

4. Socket Weld Cap

Function: Seals the end of a pipe.

Application: Used to close off pipelines or for future expansion.

5. Socket Weld Cross

Function: Allows for four-way branching of the pipeline.

Application: Used in complex piping systems where flow needs to be divided into multiple directions.

6. Socket Weld Reducer

Function: Connects pipes of different diameters.

Concentric Reducer: Aligns the centerlines of both pipes.

Eccentric Reducer: Offsets the centerlines, often used to avoid air pockets in horizontal pipelines.

Application: Used to transition between pipe sizes while maintaining flow efficiency.

Advantages of Socket Weld Pipe Fittings?

1. High-Pressure Capability: Socket weld fittings are designed to withstand high pressures, making them suitable for critical industrial uses such as oil and gas, chemical processing, and power generation.

2. Leak Prevention: The design of socket weld fittings includes a recessed area for the pipe, which allows for a secure fit and a permanent, welded connection. This design effectively prevents leaks, ensuring a tight seal.

3. Ease of Installation: Installing socket weld fittings is relatively straightforward. The pipe can be inserted into the fitting’s socket without requiring beveling or precise alignment, which simplifies the installation process and reduces labor costs.

4. Strength and Durability: The welding process used in socket weld fittings ensures robust joints that are resistant to mechanical failures. This makes them ideal for environments where reliability and long-term performance are crucial.

5. Corrosion Resistance: Many socket weld fittings are made from materials like stainless steel and alloy steel, which offer excellent resistance to corrosion. This is particularly advantageous in harsh environments where maintaining the integrity of piping systems is essential.

As a leading provider in the industry, we offer a wide range of socket weld fittings, including socket weld 45 take offs, socket weld 45 degree elbows, and forged steel socket weld caps. Additionally, we provide high-quality buttweld elbows designed for various applications. Our products are engineered to meet the rigorous demands of industrial environments, ensuring exceptional performance, durability, and corrosion resistance.

EN

EN