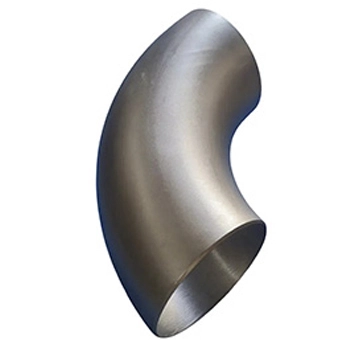

A short radius elbow is a type of pipe fitting designed to change the direction of fluid flow in a piping system. The key feature of a short radius elbow is its curvature radius, which is equal to the nominal pipe diameter (1D). This design makes it more compact compared to long radius elbows, allowing it to fit into tighter spaces.

ANSI/ASME B16.9: This standard covers factory-made wrought buttwelding fittings, including short radius elbows.

ASME B16.28: Standard for wrought steel and wrought austenitic stainless steel forged fittings.

MSS SP-43: Standard for socket-welding and threaded fittings.

DIN 2615: German standard for pipe fittings.

JIS B2311: Japanese Industrial Standard for pipe fittings.

Carbon Steel:

ASTM A105: Suitable for high-pressure systems.

ASTM A350 LF2: Low-temperature carbon steel.

ASTM A694: High-yield strength carbon steel.

Alloy Steel:

ASTM A182 F5: Alloy steel for high-temperature applications.

F9, F11, F22, F91: Various grades of alloy steel for specific high-temperature and high-pressure applications.

Stainless Steel:

ASTM A403 WP304, WP304L: Austenitic stainless steel for general corrosion resistance.

WP316, WP316L: Enhanced corrosion resistance, suitable for harsh environments.

WP317, WP321, WP347: Special grades for specific applications.

Nickel Alloys:

Inconel 600, 625, 718: High-temperature and corrosion-resistant nickel alloys.

Hastelloy C22, C276: Superior corrosion resistance in aggressive environments.

Space-saving: Ideal for tight or confined spaces.

Cost-effective: Requires less material compared to long radius elbows.

Ease of installation: Easier to fit in compact piping layouts.

Space is limited and a compact design is required.

The system operates at low pressure and flow efficiency is not critical.

The application involves non-abrasive fluids or low-velocity flows.

EN

EN