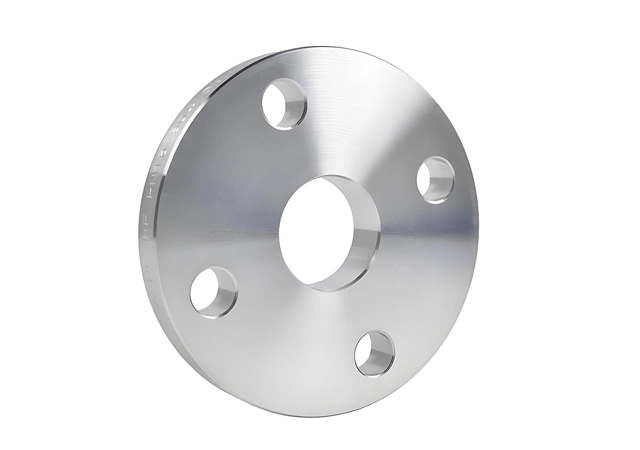

What is Plate Flange

A plate flange, also known as a plain flange, is a simple and commonly used type of flange in piping systems. It is a flat, circular plate with bolt holes evenly distributed around its perimeter. The plate flange has a flat face, which directly contacts the mating flange or the end of a pipe, fitting, or equipment. Among the popular material variants, ss plate flange (stainless steel grade) and stainless steel plate flange are highly sought after for their corrosion resistance in chemical, marine, and water treatment applications.

The primary function of a plate/plain flange is to create a connection within a piping system. It allows for the joining of pipes, valves, pumps, and other components. This connection enables the transfer of fluids, such as water, oil, gas, or chemicals, in a controlled and efficient manner. For general low-pressure and non-critical scenarios, plate flanges carbon steel and carbon steel plate flange are preferred choices due to their cost-effectiveness and reliable structural strength. For example, in a building's plumbing system, plate flanges are used to connect sections of water supply pipes. They ensure a secure and leak - tight connection, preventing any loss of water.

Types of Plate/Plain Flange

Flat Face (FF) Plate Flange: Used with flat-faced equipment like cast iron valves.

Raised Face (RF) Plate Flange: Features a raised surface for better sealing with gaskets.

Threaded Plate Flange: Includes internal threads for connecting to threaded pipes.

Sizes and Pressure Ratings of Plate/Plain Flange

Common Sizes:

Nominal Pipe Size (NPS): 1/2" to 24" (standard range)

Large Sizes: Up to 60" or more (for specialized applications)

Metric Sizes: DN15 to DN600 (or larger)

Common Pressure Classes:

ASME/ANSI Pressure Classes:

150# (PN20): Low-pressure applications.

300# (PN50): Medium-pressure applications.

400# (PN64): Intermediate pressure.

600# (PN100): High-pressure applications.

900# (PN150): Very high-pressure applications.

1500# (PN250): Extreme pressure applications.

2500# (PN420): Ultra-high-pressure applications.

PN Ratings (European Standards):

PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN320, PN400.

Standards of Plate/Plain Flange

ASME B16.5:Includes slip-on, weld neck, socket weld, threaded, and other flange types.

ASME B16.47:Divided into two series: Series A (MSS SP-44) and Series B (API 605).

ANSI B16.5:Identical to ASME B16.5, covering flanges for NPS 1/2" to 24".

ANSI B16.47:Identical to ASME B16.47, covering large-diameter flanges.

DIN EN 1092-1:Covers slip-on, weld neck, threaded, and blind flanges.

DIN 2527:Specific to slip-on flanges with raised faces.

EN 1092-1:Equivalent to DIN EN 1092-1, covering steel flanges.

EN 1759-1:Covers flanges for industrial applications, similar to ASME B16.5.

ISO 7005-1:Covers slip-on, weld neck, threaded, and blind flanges.

JIS B2220:Covers steel pipe flanges, including slip-on flanges.

GOST 12820-80:Covers slip-on flanges for PN ratings.

GOST 12821-80:Covers weld neck flanges but is often referenced alongside slip-on flanges.

Material Grade of Plate/Plain Flange

Carbon Steel Plate Flanges: Common grades like ASTM A105 and A350 LF2 are used for high-temperature, high-pressure systems in oil, gas, and general-purpose applications.

Stainless Steel Plate Flanges: Grades such as ASTM A182 F304 and F316 offer excellent corrosion resistance for food, pharmaceuticals, and corrosive environments.

Alloy Steel Plate Flanges: ASTM A182 F11 and F22 are ideal for high-temperature, high-pressure systems in refineries and power plants.

Duplex Steel Plate Flanges: Grades like ASTM A182 F51 (Duplex 2205) provide high strength and corrosion resistance for harsh environments and offshore applications.

Nickel Alloy Plate Flanges: Materials like Monel, Inconel, and Hastelloy are used in extreme conditions, such as chemical processing and offshore industries.

Applications of Plate/Plain Flange

Industrial Piping

Slip - on flanges are used in industrial plants for connecting pipes. They're suitable for various fluids, offering easy installation in chemical, petrochemical pipelines. Many projects in this sector opt for pipe plate flange due to its flat structural design and reliable connection performance in general industrial scenarios.

Power Generation

Applied in power plants' steam and water pipelines. They can withstand high - pressure and temperature, ensuring reliable connections in thermal, nuclear plants.

Water and Wastewater Systems

Used in water supply and sewage treatment. They connect pipes easily, and some materials resist corrosion from water and chemicals in these systems—stainless plate flanges are particularly favored here for their excellent corrosion resistance against moisture and chemical media.

HVAC Systems

Employed in heating, ventilation, and air - conditioning. Their simple installation and ability to handle air and refrigerant flow make them ideal for HVAC piping.

Marine Industry

Found in ships' piping like fuel, cooling lines. They can endure the ship's movement and are resistant to seawater corrosion for long - term use. Global buyers often cooperate with a professional plate flange supplier to source customized products that meet marine - grade corrosion resistance and structural requirements.

EN

EN