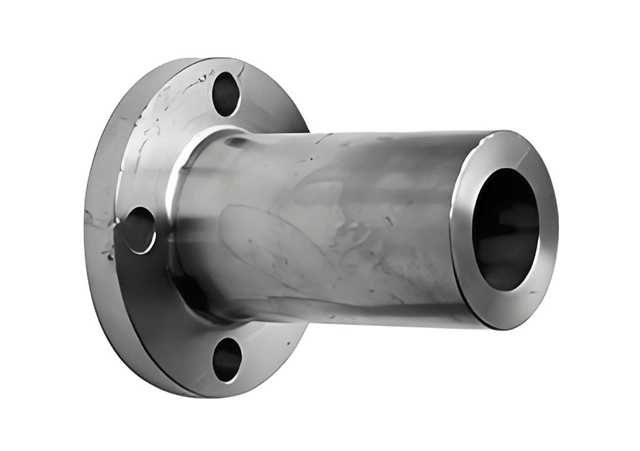

A Long Weld Neck Flange (LWN Flange) is a specialized type of flange used in industrial piping systems. It features an extended neck, which provides additional strength and stability, making it ideal for high-pressure and high-temperature applications. The extended neck acts as a boring extension, reducing stress concentration and providing a reinforced connection. LWN flanges are commonly used in industries such as oil, gas, petrochemical, and power generation.

The function of an LWN flange is to provide a secure and durable connection in demanding environments. It is designed to withstand extreme conditions, ensuring reliable performance and minimizing the risk of leaks or failures. The flange is typically made from materials like carbon steel, stainless steel, or alloy steel, which offer high strength and corrosion resistance. The extended neck also allows for better distribution of stress, reducing the risk of mechanical failure.

Heavy Barrel LWN Flange: Features a thicker neck for extra strength in extreme conditions.

Integral LWN Flange: The flange and neck are forged as a single piece for maximum strength.

LWN Flanges are available in sizes from NPS 1/2" to 60"

pressure ratings from 150# to 2500# (ASME B16.5/B16.47).

Common pressure classes include 150#, 300#, 600#, 900#, 1500#, and 2500#. Larger sizes (NPS 26" to 60") typically range from 150# to 900#. The dimensions, such as outside diameter, thickness, and bolt circle, vary based on size and pressure class.

ASME B16.5: Covers dimensions and pressure ratings for flanges up to NPS 24".

ASME B16.47: Covers large-diameter flanges for sizes NPS 26" to 60".

DIN EN 1092-1: European standard for steel flanges.

ISO 7005: International standard for flanges.

Carbon Steel: ASTM A105, A350 LF2.

Stainless Steel: ASTM A182 F304, F316, F321.

Alloy Steel: ASTM A182 F11, F22, F5.

Duplex Steel: ASTM A182 F51, F53, F55.

Nickel Alloys: Monel, Inconel, Hastelloy.

1. Oil and Gas:Pipeline flow measurement, wellhead monitoring

2. Chemical:Process control, corrosive fluid handling

3. Power Generation:Steam flow, cooling water systems, gas turbines

4. Water Treatment:Water flow, effluent monitoring, pump stations

5. Petrochemical:Process flow monitoring, pipeline systems

6. Food and Beverage:Sanitary applications, liquid ingredient monitoring

7. Pharmaceutical:Precision flow control, cleanroom applications

8. HVAC:Air and water flow measurement, energy efficiency

9. Marine and Offshore:Seawater flow, fuel monitoring

EN

EN