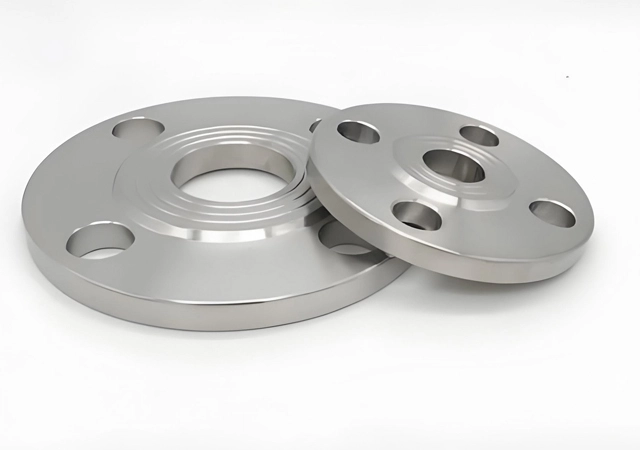

A JIS flange is a type of flange that adheres to the Japanese Industrial Standards (JIS), with jis b2220 flanges being the core compliant variant widely recognized in industrial applications. These flanges are widely used in Japan and regions influenced by Japanese engineering practices.

JIS flange are designed to provide reliable connections in piping systems, ensuring secure, leak-free joints. JIS flanges are typically used in applications with lower pressure and temperature requirements compared to other standards like ANSI.

JIS flange are commonly found in industries such as petrochemicals, manufacturing, and marine, where their robust design and standardization ensure compatibility and ease of integration.

JIS flanges are manufactured according to specific Japanese standards, such as:

JIS B 2220: Covers steel pipe flanges for general use.

JIS B 2238: Covers cast iron pipe flanges.

JIS B 2240: Covers copper alloy pipe flanges.

Pressure Ratings:

JIS flanges are classified using K rating (K stands for "Kilo"), such as 5K, 10K, 16K, 20K, 30K, 40K, and 63K. The K rating indicates the maximum allowable pressure in kgf/cm² at room temperature.

For example:

5K: Suitable for 5 kgf/cm² pressure.

10K: Suitable for 10 kgf/cm² pressure.

16K: Suitable for 16 kgf/cm² pressure.

Carbon Steel: Such as ASTM/ASME A/SA105, A/SA105N, A/SA216-WCB, DIN 1.0402, and DIN 1.0460. It has good strength and machinability and is suitable for general pressure pipeline systems.

Stainless Steel: Such as ASTM/ASME A/SA182 - F304, F304L, F316, F316L and ASTM/ASME A/SA351 - CF3, CF3M, CF8, CF8M. It has excellent corrosion resistance and heat resistance and is suitable for environments with high requirements for corrosion resistance, such as the food and pharmaceutical industries.

Alloy Steel: There are duplex stainless steels like S31803/S32205 A182 - Gr F51/F52/F53/F54/F55/F57/F59/F60/F61 and super duplex stainless steels like S32750/S32760 A182 - Gr F51/F52/F53/F54/F55/F57/F59/F60/F61. They have high strength and good corrosion resistance and are suitable for harsh environments.

Oil and Gas: High-pressure and high-temperature pipelines.

Chemical Industry: Corrosive and hazardous environments.

Water Treatment: Low-pressure, non-corrosive systems.

Power Generation: Steam and water pipelines in power plants.

Industrial Processing: Connections in refineries, petrochemical plants, and food processing.

EN

EN