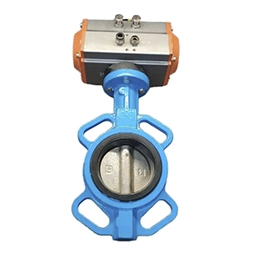

The groove butterfly valve—officially recognized as grooved type butterfly valve and belonging to the practical category of grooved end valve—features a grooved end connection for quick installation, ideal for fire protection, HVAC, and water systems. Its compact design, 90-degree operation, and durable materials like ductile iron and EPDM seals ensure reliable performance, easy maintenance, and cost-effectiveness in various industrial applications.

Easy to install: no welding or flanges are required, saving installation time and cost.

Easy to maintain: simple structure, easy to disassemble and repair.

Space saving: compact design, suitable for occasions with limited space.

Economical and practical: low manufacturing cost, low installation and maintenance costs.

Valve body: commonly used ductile iron, cast steel or stainless steel, strong corrosion resistance.

Butterfly plate: stainless steel or aluminum alloy, light and corrosion resistant.

Sealing ring: EPDM, NBR or PTFE, suitable for different media and temperatures.

In short, the groove butterfly valve has become one of the commonly used valves in the pipeline system due to its convenient installation, good sealing, economy and practicality.

EN

EN