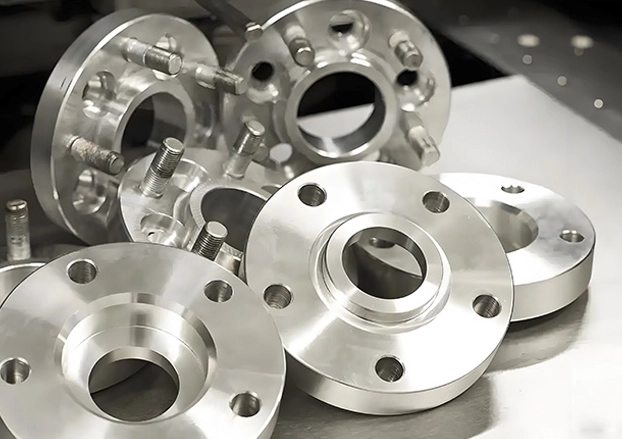

Manufacturing process of steel flange

The manufacturing process of steel flange mainly includes three methods: forging, stamping and welding. Forged flange is formed by heating steel billet and forging. It has high strength and good toughness and is suitable for high pressure and high temperature environment.

Stamped flange uses a punch press to stamp steel plate. The process is simple and efficient, but the strength is relatively low.

Welded flange is welded with flange plate and short pipe, which is suitable for large diameter flange. Different processes are suitable for different working conditions to meet diverse industrial needs.

EN

EN