An EN flange is a type of flange that conforms to the standards set by the European Committee for Standardization (CEN), which is recognized by the abbreviation EN (Europäische Norm). Among the key European flange standards, en 1092 2 flanges are a specialized variant that meets specific technical requirements for industrial piping connections.

EN flanges are widely used in Europe and other regions that adopt European standards for piping systems. These flanges are designed to ensure compatibility, safety, and reliability in various industrial applications, including oil and gas, chemical, water treatment, and power generation.

Weld Neck Flange (WN): For high-pressure applications.

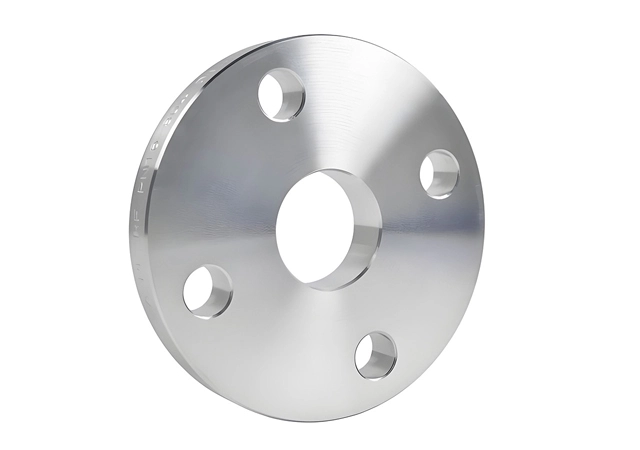

Slip-On Flange (SO): Easy to install, used in low-to-medium pressure systems.

Blind Flange (BL): Used to seal the end of a pipeline.

Threaded Flange (TH): For low-pressure, non-critical applications.

Lap Joint Flange (LJ): Used with stub ends for easy alignment.

Orifice Flange: For flow measurement applications.

EN flanges are manufactured according to specific European standards, such as:

EN 1092-1: Covers circular steel flanges (PN designated) for pipes, valves, fittings, and accessories.

EN 1759-1: Covers circular flanges (Class designated) based on ASME B16.5 and B16.47 standards.

EN 1092-2: Covers cast iron flanges.

EN 1092-3: Covers copper alloy flanges.

EN 1092-4: Covers aluminum alloy flanges.

Pressure Ratings:

EN flanges are classified using PN (Pressure Nominale) ratings, such as PN6, PN10, PN16, PN25, PN40, PN63, PN100, and PN160. The PN rating indicates the maximum allowable pressure in bars at 20°C.

For example:

PN10: Suitable for 10 bar pressure at 20°C.

PN16: Suitable for 16 bar pressure at 20°C.

Carbon Steel ASME flange:

EN flanges use carbon steels like S235JR, S355JR for general use, and pressure vessel steels like P235GH, P265GH, P355GH, 16Mo3 for high-pressure. They vary in properties for different applications.

Stainless Steel ASME flange:

Austenitic stainless steels like F304, F304L, F316, F316L are common. Duplex stainless steel X2CrNiMoN22-5-3 combines austenitic and ferritic advantages, with high strength and corrosion resistance.

Alloy Steel ASME flange:

Chromium-molybdenum steels such as 13CrMo4-5 and 10CrMo9-10 are alloy steels for EN flanges. They have excellent high-temperature strength, creep and oxidation resistance, for high-temperature and high-pressure systems.

Oil and Gas Industry: It is used in oil and gas pipelines for the connection of various pipelines and equipment.

Chemical Industry: In chemical plants, it is used to connect pipelines transporting various chemical media.

Power Industry: It is used in power generation systems, such as in the pipelines of thermal power plants and nuclear power plants.

Water Treatment Industry: It is used in water supply and drainage systems, like in the pipelines of water treatment plants and water desalination plants.

Shipbuilding Industry: It is used in the piping systems on ships to ensure the connection and sealing of various pipelines.

EN

EN