An eccentric reducer is a type of pipe fitting designed to connect two pipes of different diameters while offsetting the centerline of the smaller pipe from that of the larger one.This offset design allows fluid or gas to flow smoothly, preventing the formation of air pockets or fluid accumulation, which can be crucial in certain applications.

Eccentric reducers are commonly used in horizontal piping systems, such as those in HVAC, plumbing, and industrial processes, where maintaining a consistent flow and preventing turbulence is important. They are particularly useful in systems that handle fluids with varying densities or where air and liquid need to be separated efficiently.

Butt-Welding Reducers: These are welded directly to the pipes, ensuring a strong and leak-resistant connection.

Threaded Reducers: These have threaded ends, allowing for easy installation without welding, commonly used in small-diameter piping systems.

Flanged Reducers: These come with flanges that can be bolted to corresponding flanges on pipes or other equipment, facilitating easy maintenance and disassembly

Offset Design: The offset centerline creates a flat side, which can be positioned to prevent air or liquid accumulation.

Flow Management: Helps in managing fluid flow by directing it along the angled side, reducing turbulence and air entrapment.

Noise Reduction: Absorbs noise generated by fluid movement and pipe walls, decreasing overall vibration.

Carbon Steel Eccentric Reducer

Properties: High strength, cost-effective, suitable for high-pressure systems.

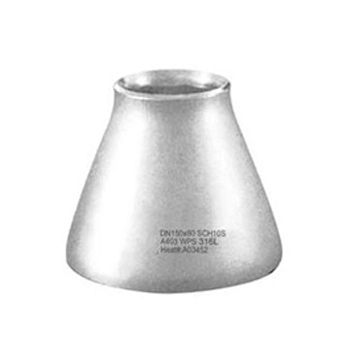

Stainless Steel Eccentric Reducer

Properties: Excellent corrosion resistance, ideal for food processing and chemical industries.

Common Grades: SS304, SS316, SS304L, SS316L.

Alloy Steel Eccentric Reducer

Properties: Enhanced resistance to heat and pressure, used in extreme environments.

Common Grades: WP11, WP22, WP91.

Duplex and Super Duplex Stainless Steel Eccentric Reducer

Properties: High strength and excellent corrosion resistance, particularly in aggressive environments.

Common Grades: UNS S31803 (duplex), UNS S32750 (super duplex).

Oil and Gas: For pipeline systems transporting crude oil, natural gas, and refined products.

Chemical Processing: In corrosive and high-temperature environments.

Water Treatment: For connecting pipes in water distribution and treatment systems.

HVAC Systems: In heating, ventilation, and air conditioning systems.

Power Generation: In steam and cooling water pipelines.

Pharmaceuticals: For sanitary piping systems requiring smooth flow transitions.

Food and Beverage: In hygienic piping systems for liquid and gas transport.

EN

EN