Cold drawn seamless steel pipe is a precision cold drawn seamless pipe with high dimensional accuracy and good surface finish used in mechanical structures and hydraulic equipment, and it is also commonly known as high-performance cold drawn seamless pipe in the industry. The use of seamless steel pipes to manufacture mechanical structures or hydraulic equipment can greatly save machining hours, improve material utilization, and at the same time help improve product quality.

If you want to obtain small-diameter seamless steel pipes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of the two. Cold rolling is usually carried out on a two-roll mill, and the steel pipe is rolled in an annular pass composed of a variable cross-section circular groove and a fixed conical head. Cold drawing is usually performed on a 0.5 to 100T single-chain or double-chain cold drawing machine, which is the core processing method for producing seamless cold drawn steel tube.

High-quality carbon structural steel cold-drawn seamless pipes are mainly made of No. 10, No. 20, No. 35, and No. 45 steel. In addition to ensuring the chemical composition and mechanical properties, hydrostatic testing, curling, flaring, flattening, etc. test, and these strict tests also apply to cold drawn steel pipe.

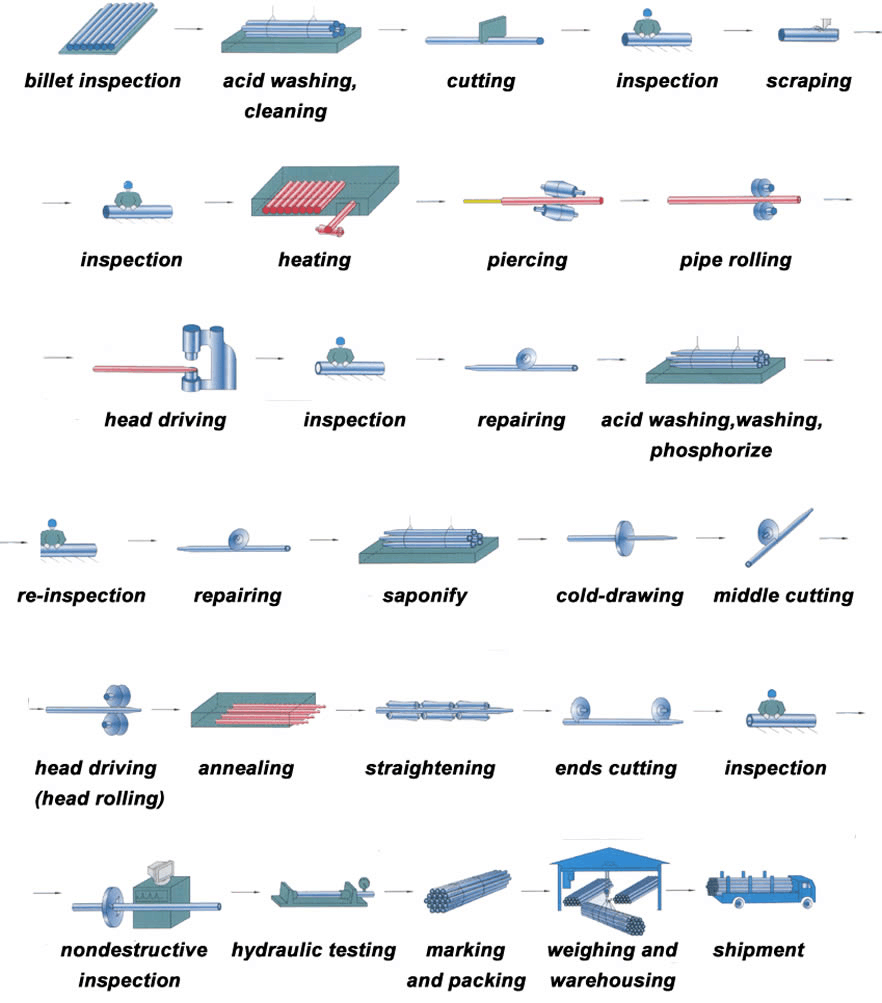

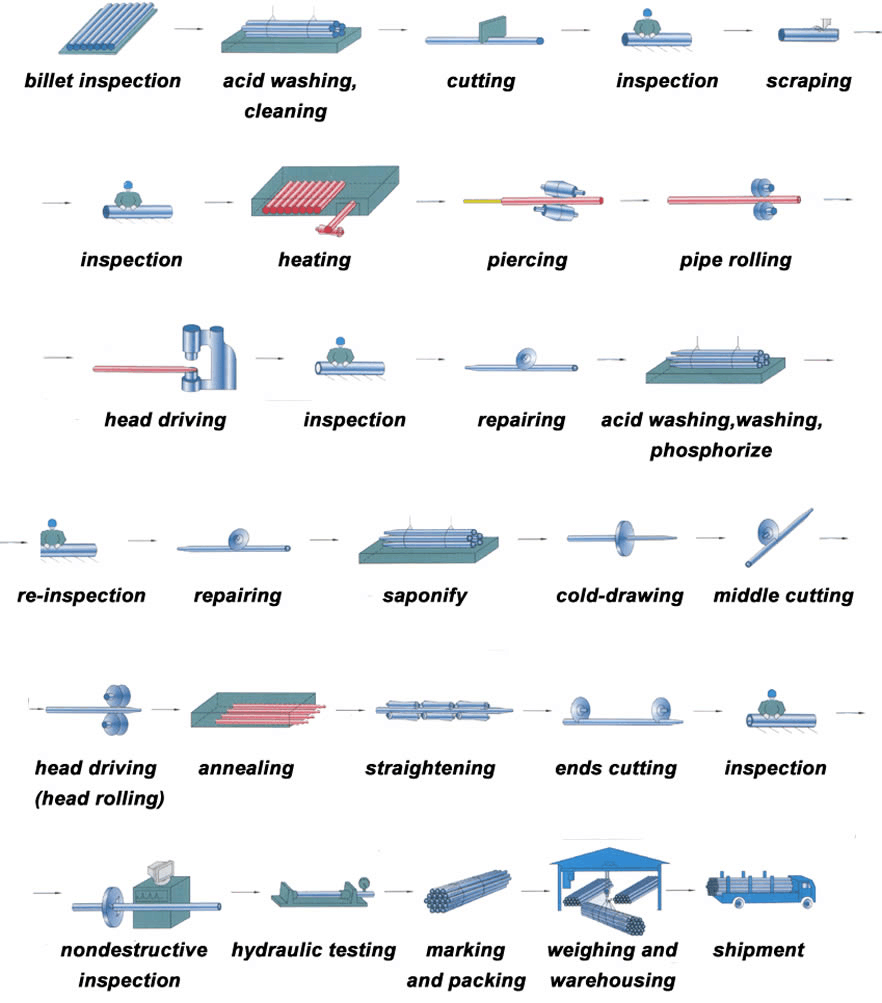

Round tube → heating → perforation → Heading → annealing → pickling → oiled (copper) → multi-pass cold drawn (cold rolled) → blank tube → heat treatment → straightening →hydrostatic testing (testing) → mark → storage.

EN

EN