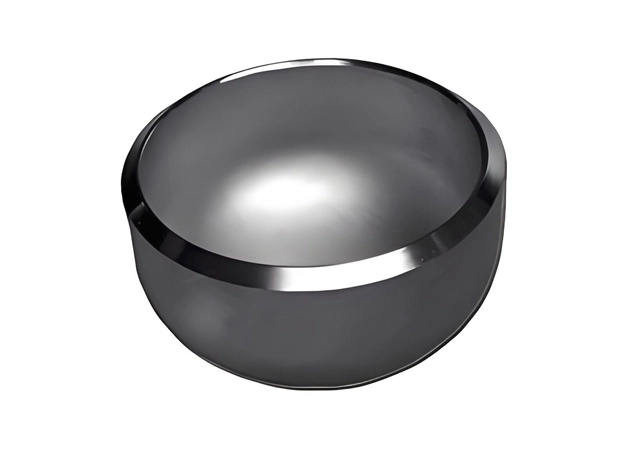

What is Carbon Steel Pipe Caps

Carbon steel pipe caps are essential fittings designed to seal the ends of carbon steel pipes. Crafted from an iron - carbon alloy, they possess high strength and good ductility, enabling them to withstand significant mechanical stress and pressure, and the reliable carbon steel end cap is a core variant of this sealing fitting category.

The common types are butt - weld, socket - weld, and threaded pipe caps. Butt - weld caps offer a strong and permanent connection, making carbon steel weld cap a preferred choice for high-pressure industrial pipelines; socket - weld caps have a socket for pipe insertion and then are welded; threaded caps can be easily screwed onto the pipe, with carbon steel pipe end caps also covering these multi-type sealing solutions for diverse installation needs.

These caps find wide applications across multiple industries. In the oil and gas sector, they seal pipeline ends during construction and maintenance. Power plants use them in steam and water pipelines. They're also present in general industrial piping systems for transporting fluids, gases, or solids, as well as in building construction for plumbing and heating, and carbon steel pipe caps as the general category are indispensable for ensuring pipeline integrity in all these scenarios.

Types of Carbon Steel Pipe Caps

Butt - Weld Caps: Welded directly to pipes, strong for high - pressure use in oil & gas pipelines.

Socket - Weld Caps: Pipes inserted into sockets and welded, easy for small - diameter systems in chemical plants.

Threaded Caps: Screwed onto pipes, convenient for installation/removal in plumbing and low - pressure industries.

Round Caps: Fit round pipes, commonly used for fluid and gas transport in various industries.

Square/Rectangular Caps: For non - circular pipes, used in specialized or custom - made piping systems.

Advantages of Carbon Steel Pipe Caps

Cost-Effective: Carbon steel is generally less expensive than stainless steel or other high-performance materials.

Wide Availability: Easily available in various sizes and thread types.

Strength: Suitable for applications requiring high mechanical strength.

Versatility: Can be used in a wide range of industrial and commercial applications.

Standards for Carbon Steel Pipe Caps

ASME B16.9: Covers carbon steel buttwelding pipe caps, specifying dimensions, tolerances and material requirements.

MSS SP - 43: Focuses on wrought carbon steel caps, providing guidelines for manufacturing, testing and inspection.

EN 10253: Deals with carbon steel butt - welding caps in Europe, defining materials, dimensions and testing methods.

DIN Standards: Such as DIN 2617, specify dimensions and delivery conditions for carbon steel pipe caps.

GB/T 12459: China's standard for steel butt - welding caps, covering various aspects like requirements and packaging.

Connection of Carbon Steel Pipe Caps

Butt - Welding Connection:

The end of the cap is directly welded to the pipe end after beveling. Welding methods like SMAW are used. It offers a strong, permanent joint for high - pressure applications but needs skilled welders and is hard to disassemble.

Socket - Welding Connection:

The pipe is inserted into the cap's socket and a fillet weld is made around the socket edge. It's easy for small - diameter pipes and limited - space areas, but has lower strength than butt - welding.

Threaded Connection:

The cap with matching threads is screwed onto the pipe, sometimes with sealing compounds. It's easy for installation and removal in low - pressure systems but may leak or loosen over time.

Applications of Carbon Steel Pipe Caps

Oil and Gas Industry: Used to seal pipelines and equipment, ensuring safety and integrity in high-pressure systems.

Chemical Processing: Prevent leaks in reactors and piping systems, containing hazardous materials under high temperature and pressure.

Water Treatment: Seal pipes in water treatment plants and distribution systems to prevent contamination.

General Industrial Use: Suitable for sealing pipes handling corrosive media, offering structural stability.

Plumbing Systems: Seal pipes in residential and commercial plumbing, withstanding high pressure and temperature.

HVAC Systems: Prevent leaks of refrigerants and fluids, ensuring efficiency and safety in heating and cooling systems.

EN

EN