Grades of Alloy Steel Used for Elbows

Chromium-Molybdenum (Cr-Mo) Alloy Steels:ASTM A234 WP5/WP9/WP11/WP22/WP91

WP5: Contains 5% chromium and 0.5% molybdenum.

WP9: Contains 9% chromium and 1% molybdenum.

WP11: Contains 1.25% chromium and 0.5% molybdenum.

WP22: Contains 2.25% chromium and 1% molybdenum.

WP91: Contains 9% chromium and 1% molybdenum, with added vanadium and niobium for high-temperature strength.

Applications: High-temperature and high-pressure applications, such as power plants, refineries, and petrochemical industries.

Nickel Alloy Steels:ASTM A420 WPL6

Contains nickel for improved low-temperature toughness.

Applications: Low-temperature environments, such as cryogenic applications.

High-Yield Strength Alloy Steels:ASTM A860 WPHY 42/52/60/65/70

High-yield strength alloy steels for high-pressure applications.

Applications: Oil and gas pipelines, offshore platforms, and high-pressure systems.

Other Alloy Steels:

ASTM A691: Used for high-temperature and high-pressure service, often in power plants.

ASTM A335: Used for high-temperature service in power plants and refineries.

Applications of Alloy Steel Elbows

1. Chemical and Petrochemical Industries:Resistant to corrosive chemicals and high temperatures.

2. Food and Beverage Industry:Hygienic and easy to clean, meeting strict sanitary standards.

3. Pharmaceutical Industry:Non-reactive and suitable for sterile environments.

4. Oil and Gas Industry:Used in pipelines and offshore platforms due to high strength and corrosion resistance.

5. Water Treatment and Desalination Plants:Resistant to saltwater and chlorine corrosion.

6. HVAC Systems:Used in heating, ventilation, and air conditioning systems for durability and corrosion resistance.

Alloy steel elbows are essential components in piping systems that require high strength, toughness, and resistance to extreme temperatures and pressures. They are made from steel alloys containing elements like chromium, molybdenum, nickel, and vanadium, which enhance their mechanical and chemical properties.

Common grades include ASTM A234 WP5/WP9/WP11/WP22/WP91 and ASTM A420 WPL6, used in industries like power generation, oil and gas, petrochemicals, and aerospace. Their durability, versatility, and performance make them ideal for demanding applications.

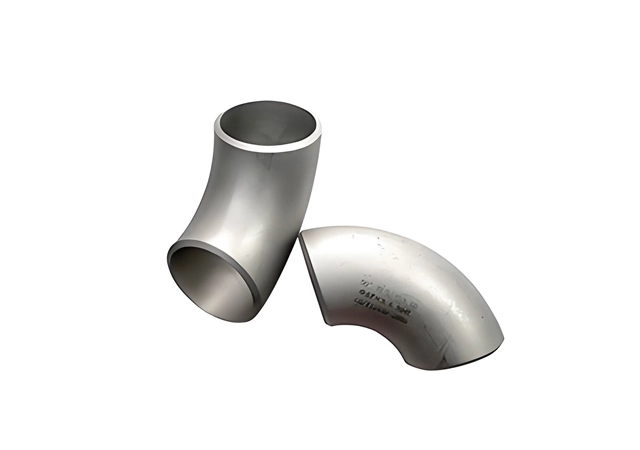

What is Alloy Steel Elbow

An alloy steel elbow is a type of pipe fitting used to change the direction of fluid flow in a piping system, and this high-performance alloy steel elbow is widely favored for its excellent adaptability to harsh working conditions. It is made from alloy steel, which offers enhanced strength and durability, making it suitable for high-pressure and high-temperature applications. These elbows are commonly used in demanding industrial environments such as power generation and petrochemical industries. They are available in various angles (e.g., 45°, 90°, 180°) and can be manufactured to meet standards like ASTM A234, ensuring each alloy steel elbow meets strict industrial quality requirements.

Parameter of Alloy Steel Elbow

| Parameter | Details |

| Standards | - ASTM A234: Medium and low-pressure systems<br>- ASTM A106 Gr.B: High-temperature, high-pressure<br>- ASTM A105: High-pressure systems<br>- ASTM A53 Gr.B: Medium and low-pressure<br>- EN 10216-1 P235TR1/P235TR2: European standard for medium and low-pressure |

| Size Range | - Nominal Pipe Size (NPS): 1/2" to 48" |

| Wall Thickness | - SCH 10: Low-pressure<br>- SCH 40: Medium-pressure<br>- SCH 80: High-pressure<br>- SCH 160: Extremely high-pressure |

| Bending Radius (R) | - Long Radius (LR): 1.5 times the pipe diameter (1.5D)<br>- Short Radius (SR): Equal to the pipe diameter (1D) |

| Surface | - Finish: Smooth, polished to reduce corrosion and ensure efficient fluid flow<br>- Coating Options: Black painted, epoxy coated, galvanized, varnished |

Alloying Elements in Alloy Steel Elbows

Chromium (Cr): Improves hardness, corrosion resistance, and high-temperature strength.

Molybdenum (Mo): Enhances strength, toughness, and resistance to high temperatures and creep.

Nickel (Ni): Improves toughness, corrosion resistance, and low-temperature performance.

Vanadium (V): Increases strength, wear resistance, and fatigue resistance.

Manganese (Mn): Improves hardenability and strength.

Silicon (Si): Enhances strength and oxidation resistance.

Types of Alloy Steel Elbows

Based on Angle:

90° Elbow: Changes the direction of flow by 90 degrees.

45° Elbow: Changes the direction of flow by 45 degrees.

180° Elbow (Return Bend): Reverses the direction of flow completely.

Based on Connection Type:

Butt-Weld Elbows: Welded directly to the pipe for a seamless and strong connection.

Socket-Weld Elbows: Fitted into a socket and welded for smaller pipe sizes.

Threaded Elbows: Screwed onto threaded pipes for easy installation and removal.

Flanged Elbows: Bolted to flanges for easy assembly and disassembly.

Based on Radius:

Short Radius (SR) Elbows: Have a smaller bend radius, making them compact but with higher pressure drop.

Long Radius (LR) Elbows: Have a larger bend radius, reducing pressure drop and allowing smoother flow.

EN

EN