A 180-degree elbow is a type of pipe fitting designed to change the direction of fluid flow by 180 degrees, effectively creating a U-turn in the piping system. This fitting is crucial in applications where a complete reversal of flow direction is required, such as in complex industrial piping systems, heat exchangers, and other arrangements where fluids or gases need to flow in the opposite direction.

Flow Direction Change: The primary function of a 180-degree elbow is to reverse the direction of fluid flow completely.

Reduced Turbulence: The design of the elbow ensures a smooth flow transition, minimizing turbulence and pressure drop.

Space Efficiency: Available in both long radius (LR) and short radius (SR) forms, the short radius version is more compact and suitable for space-constrained environments.

Threaded 180-Degree Elbow:

Has threaded ends for screwing onto pipes.

Commonly used in low-pressure systems like plumbing.

Socket Weld 180-Degree Elbow:

Pipes are inserted into the fitting and welded for a strong connection.

Used in high-pressure systems.

Butt Weld 180-Degree Elbow:

Pipes and fittings are welded together end-to-end.

Ideal for high-pressure and high-temperature applications.

Flanged 180-Degree Elbow:

Has flanged ends for bolted connections.

Used in systems requiring frequent disassembly.

Long Radius (LR) 180-Degree Elbow

Description: The long radius elbow has a curvature radius that is typically 1.5 times the pipe diameter. This design provides a smoother flow transition, reducing turbulence and pressure drop.

Applications: Ideal for high-pressure and high-flow rate systems where minimizing pressure loss is crucial. Commonly used in industrial applications such as chemical plants, refineries, and power plants.

Short Radius (SR) 180-Degree Elbow

Description: The short radius elbow has a curvature radius equal to the pipe diameter. This design is more compact and suitable for tight spaces.

Applications: Used in systems where space is limited and high-pressure conditions are not a primary concern. Common in residential plumbing and smaller industrial setups.

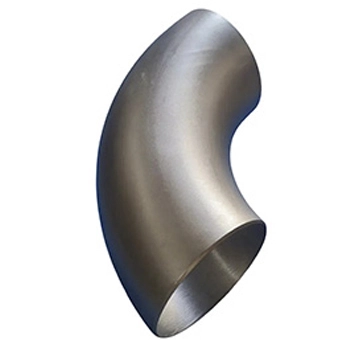

Stainless Steel 180-Degree Elbow

Description: Made from stainless steel, these elbows offer excellent corrosion resistance and are suitable for a wide range of applications.

Applications: Widely used in food processing, pharmaceuticals, and other industries where hygiene and corrosion resistance are critical. Also used in chemical processing and HVAC systems.

Carbon Steel 180-Degree Elbow

Description: Made from carbon steel, these elbows are strong and durable, suitable for high-pressure applications.

Applications: Commonly used in oil and gas, chemical processing, and power plants where high strength and durability are required.

Alloy Steel 180-Degree Elbow

Description: Made from alloy steel, these elbows offer enhanced strength and corrosion resistance compared to carbon steel.

Applications: Used in high-pressure and high-temperature applications, such as in power plants and refineries.

Heat Exchangers: Used to reverse the flow of fluids, enhancing heat transfer efficiency.

Industrial Piping: Used in chemical and oil refineries to recirculate fluids.

HVAC Systems: Helps control airflow by redirecting air in compact duct systems.

Water Supply Systems: Used in systems where a complete reversal of flow direction is required.

EN

EN