Butt-weld eccentric reducers are specialized pipe fittings designed to connect pipes of different diameters while offsetting the centerline of the smaller pipe from that of the larger one. This unique design helps prevent the accumulation of air or liquid in the pipeline, ensuring smoother fluid flow and reducing turbulence.

Butt-weld eccentric reducers are essential components in piping systems, providing efficient fluid flow management and preventing operational issues. Their adherence to industry standards ensures compatibility and reliability, making them a preferred choice for various industrial applications.

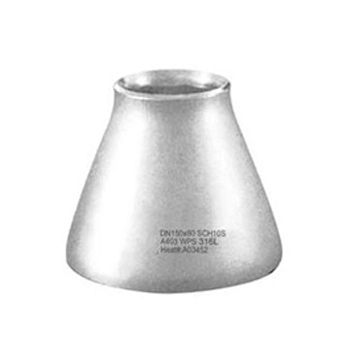

Concentric Reducers: These reducers have a symmetrical design with both ends aligned along the same centerline. They are used when the pipes need to maintain a consistent flow without any offset.

Eccentric Reducers: These reducers have one end offset from the centerline, creating a flat side. They are typically used in horizontal pipelines to prevent the accumulation of air or gases.

Durability: Made from high-quality materials, butt weld reducers are highly durable and resistant to corrosion.

Strength: The welded connection provides superior strength compared to threaded or socket weld fittings.

Smooth Flow Transition: The design ensures minimal turbulence and pressure drop during fluid flow.

Carbon Steel: ASTM A234 WPB

Commonly used for general-purpose applications.

Stainless Steel: ASTM A403 WP304/304L, WP316/316L

Offers excellent corrosion resistance and is used in harsh environments.

Alloy Steel: ASTM A234 WP5, WP9, WP11

Provides enhanced strength and resistance to high temperatures.

Nickel Alloys: ASTM B366 UNS N04400, UNS N06625

Used in highly corrosive or high-temperature environments.

Oil and Gas: For transporting crude oil, natural gas, and refined products.

Chemical Processing: In pipelines carrying corrosive chemicals.

Power Generation: In steam and water pipelines within power plants.

Water Treatment: For connecting different sizes of pipes in water treatment facilities.

Pharmaceutical: In sanitary piping systems requiring high purity and cleanliness.

EN

EN