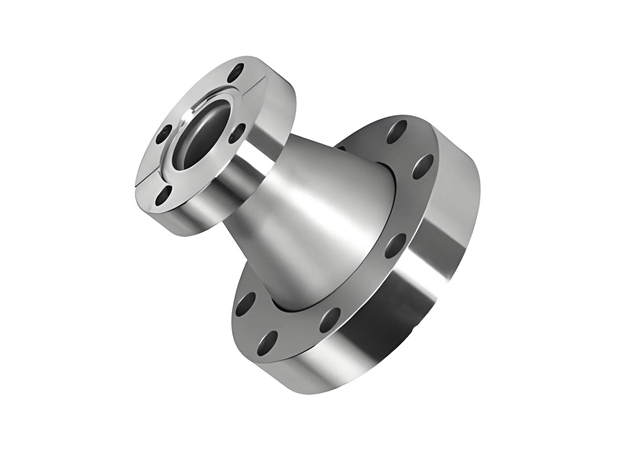

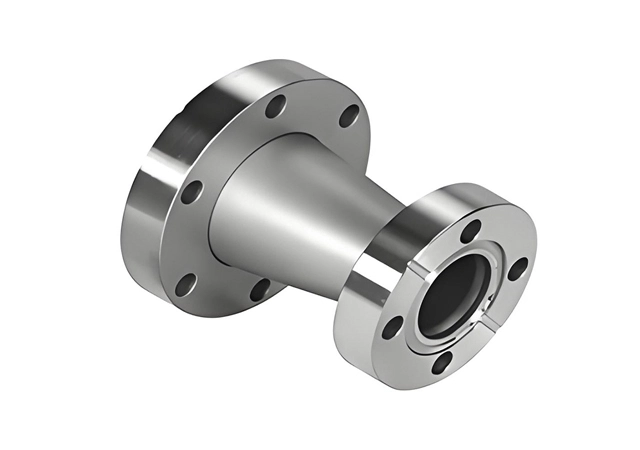

What is Reducing Flange

A reducing flange is a specialized type of pipe fitting used to connect pipes of different diameters in a piping system. It features a larger diameter on one side and a smaller diameter on the other, allowing for a smooth transition between the two pipe sizes. Among the material variants, stainless steel reducing flange is highly favored for its corrosion resistance in chemical, marine, and high-purity fluid applications. This design enables precise control and regulation over fluid or gas flow, making it an essential component in various industrial applications.

A reducing flange consists of two flanges connected by a small section of pipe or tubing. The inside diameter of this connecting section matches the exterior diameter of both flanges, facilitating a seamless transition and ensuring an effective seal. These flanges are available in various types, including weld-neck, slip-on, threaded, lap-joint, and reducing blind flange (a specialized variant that combines diameter reduction with end-sealing functionality for unused pipe branches), each offering unique advantages for different applications.

The primary function of a reducing flange is to connect pipes of different sizes while maintaining system integrity and preventing leaks. By reducing the diameter from one end to the other, it allows for precise control over fluid flow and pressure regulation. Reducing flanges are particularly useful in complex piping systems where space constraints or specific design requirements necessitate such connections.

Types of Reducing Flange

Weld Neck Reducing Flange:

Features a long tapered hub for high-stress applications.

Provides a smooth transition between pipes of different sizes.

Slip-On Reducing Flange:

Slides over the pipe and is welded in place.

Suitable for low-pressure systems.

Threaded Reducing Flange:

Includes internal threads for connecting to threaded pipes.

Used in low-pressure systems where welding is not feasible.

Socket Weld Reducing Flange:

Designed for small-diameter, high-pressure piping systems.

Provides a smooth bore for better flow characteristics.

Sizes and Pressure Ratings of Reducing Flange

Common Sizes:

Nominal Pipe Size (NPS): 1/2" to 24" (standard range)

Large Sizes: Up to 60" or more (for specialized applications)

Metric Sizes: DN15 to DN600 (or larger)

Common Pressure Classes:

ASME/ANSI Pressure Classes:

150# (PN20): Low-pressure applications.

300# (PN50): Medium-pressure applications.

400# (PN64): Intermediate pressure.

600# (PN100): High-pressure applications.

900# (PN150): Very high-pressure applications.

1500# (PN250): Extreme pressure applications.

2500# (PN420): Ultra-high-pressure applications.

PN Ratings (European Standards):

PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN320, PN400.

Standards of Reducing Flange

ASME Standards (USA): ASME sets widely used flange standards globally. ASME B16.5 covers flanges for sizes NPS 1/2" to 24", including reducing flanges of various types, with pressure classes up to 2500#. ASME B16.47 covers large-diameter flanges for sizes NPS 26" to 60", with pressure classes up to 900#.

ANSI Standards (USA): ANSI collaborates closely with ASME. ANSI B16.5 and B16.47 are identical to ASME B16.5 and B16.47, covering flanges for specific sizes and pressure classes.

DIN Standards (Germany): DIN provides widely used European flange standards. DIN EN 1092-1 covers circular steel flanges, including reducing flanges, with pressure ratings up to PN400 and sizes from DN10 to DN4000.

EN Standards (Europe): CEN provides unified European flange standards. EN 1092-1 is equivalent to DIN EN 1092-1, covering steel flanges. EN 1759-1 covers flanges for industrial applications, similar to ASME B16.5.

ISO Standards (International): ISO provides global flange standards. ISO 7005-1 combines various standards into a single international standard, covering reducing flanges with PN and Class designations.

JIS Standards (Japan): JIS provides flange specifications for Japan and Asia. JIS B2220 covers steel pipe flanges, including reducing flanges, with pressure ratings up to 63K.

GOST Standards (Russia): GOST standards are used in Russia and CIS countries. GOST 12820-80 covers slip-on flanges, including reducing flanges, for PN ratings. GOST 12821-80 covers weld neck flanges, often referenced with reducing flanges.

Material Grade of Reducing Flange

Carbon Steel: ASTM A105, A350 LF2.

Stainless Steel: ASTM A182 F304, F316, F321.

Alloy Steel: ASTM A182 F11, F22, F5.

Duplex Steel: ASTM A182 F51, F53, F55.

Nickel Alloys: Monel, Inconel, Hastelloy.

Applications of Reducing Flange

1. Oil and Gas:Pipeline flow measurement, wellhead monitoring

2. Chemical:Process control, corrosive fluid handling

3. Power Generation:Steam flow, cooling water systems, gas turbines

4. Water Treatment:Water flow, effluent monitoring, pump stations

5. Petrochemical:Process flow monitoring, pipeline systems

6. Food and Beverage:Sanitary applications, liquid ingredient monitoring

7. Pharmaceutical:Precision flow control, cleanroom applications

8. HVAC:Air and water flow measurement, energy efficiency

9. Marine and Offshore:Seawater flow, fuel monitoring

EN

EN