What are the different types of reducers in piping?

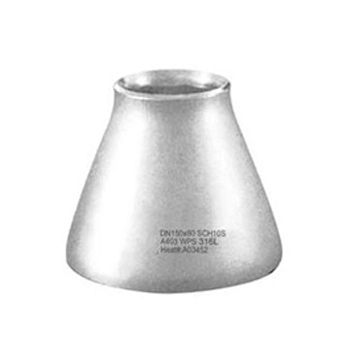

Concentric reducer: The centers of the two ends of the pipe are on the same axis, which has little interference with the fluid flow and is suitable for the diameter change of gas or vertical liquid pipelines.

Eccentric reducer: The centers of the two ends of the pipe are not on the same axis, and there are two installation methods: top flat and bottom flat. Top flat installation is suitable for pump inlet, which is conducive to exhaust; bottom flat installation is suitable for regulating valves, which is convenient for exhaust.

Classification by connection method:

Welded reducer: commonly used in pipeline systems with high strength requirements.

Threaded reducer: suitable for small and medium diameter pipelines, easy to install and disassemble.

Socket welding connection: insert the pipe into the socket of the reducer and connect it by welding.

Classification by material:

Carbon steel reducer: high strength, low cost, suitable for general industrial pipelines.

Stainless steel reducer: strong corrosion resistance, suitable for special environments such as food and chemical industry.

EN

EN