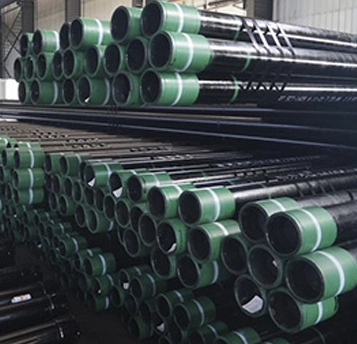

Oil and gas pipelines, high-quality products crafted by professional oil and gas pipe manufacturers, are engineered conduits used to transport crude oil, refined petroleum products, and natural gas over long distances. These pipelines are typically constructed from high-strength steel or other durable materials, designed to withstand high pressures and harsh environmental conditions. They are essential for the energy sector, ensuring the reliable and efficient delivery of hydrocarbons from production sites to refineries, processing plants, and distribution terminals, and are widely supplied by trusted oil and gas pipe suppliers.

Classification by use:

Oil pipeline: used to transport crude oil or refined oil.

Gas pipeline: used to transport natural gas or liquefied natural gas (LNG).

Gathering pipeline: used to transport oil and gas from the wellhead to the processing facility.

Distribution pipe: used to distribute refined oil or natural gas to end users.

Classification by material:

Carbon steel pipe: commonly used material, low cost, suitable for general working conditions.

Alloy steel pipe: add elements such as chromium and molybdenum to improve corrosion resistance and strength.

Stainless steel pipe: used in highly corrosive environments.

Composite material pipe: such as fiberglass pipe, used in special environments.

Classification by manufacturing process:

Seamless pipe: manufactured by hot rolling or cold drawing process, without welds, high strength.

Welded pipe: made by rolling and welding steel plates, with low cost and suitable for low-pressure environment.

The design, manufacture and use of oil and gas pipes must comply with international or industry standards, such as:

API (American Petroleum Institute) standards: such as API 5L (Line Pipe Specification).

ISO (International Organization for Standardization) standards: such as ISO 3183 (Steel pipes for oil and gas industry pipeline transportation systems).

ASTM (American Society for Testing and Materials) standards: such as ASTM A106 (Seamless carbon steel pipes for high temperature use).

EN

EN