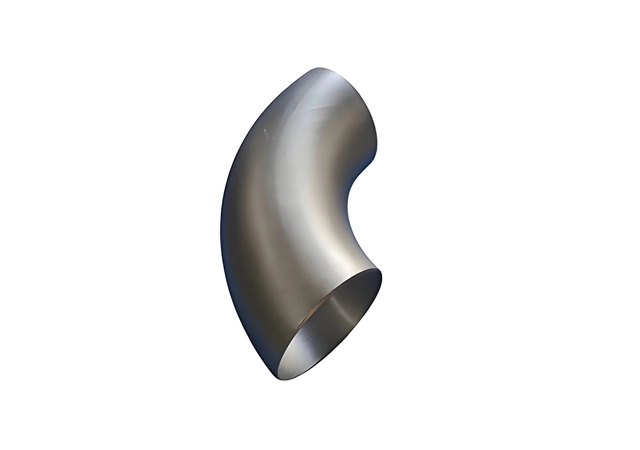

1. Radius of Curvature:The radius of a long radius elbow is typically 1.5 times the nominal pipe size (NPS). For example, for a 4-inch pipe, the radius of the elbow would be 6 inches.

In some cases, the radius can be up to 3 times the nominal pipe size, depending on the application and standards.

2. Smooth Flow Transition:The longer radius provides a gentler curve, which reduces pressure drop and turbulence in the flow. This makes it ideal for applications where fluid efficiency is critical.

3. Applications:Long radius elbows are commonly used in systems where low resistance to flow is required, such as in high-pressure pipelines, slurry transport, and pneumatic conveying systems.

They are also preferred in applications involving viscous fluids or where erosion and corrosion are concerns.

4. Standards:Long radius elbows are manufactured according to various standards, such as ASME B16.9 (for welded fittings) and ASME B16.11 (for threaded and socket-weld fittings).

5. Materials:They can be made from a variety of materials, including carbon steel, stainless steel, alloy steel, and other materials depending on the application.

A long radius elbow is a type of pipe fitting designed to change the direction of fluid flow in a piping system. The key feature of a long radius elbow is its curvature radius, which is 1.5 times the nominal pipe diameter (1.5D). This design provides a smoother flow transition compared to short radius elbows, reducing turbulence and pressure drop.

Long radius elbows are typically manufactured to meet industry standards such as:

ANSI/ASME B16.9: Factory-Made Wrought Buttwelding Fittings

ASTM A234: Wrought Carbon Steel and Alloy Steel Fittings for Medium-Pressure Service

DIN 2615: German standard for pipe fittings

JIS B2311: Japanese Industrial Standard for pipe fittings

Industrial Piping Systems: Used in oil and gas, chemical processing, and power generation.

HVAC Systems: Ideal for air and fluid distribution in heating, ventilation, and air conditioning systems.

Water Supply Systems: Commonly used in municipal water supply and distribution networks.

Food and Beverage Industry: Used in systems where hygiene and cleanliness are critical.

EN

EN