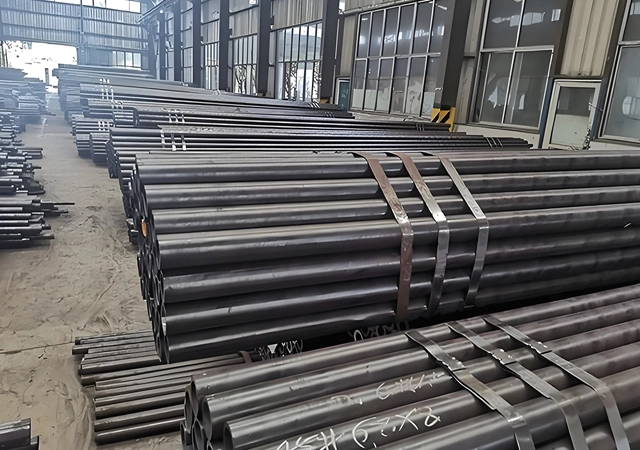

Hydraulic pillar pipes are specialized steel pipes used in hydraulic systems, particularly in hydraulic cylinders or hydraulic pillars. These pipes are designed to withstand high pressure, heavy loads, and dynamic forces, making them essential components in applications such as hydraulic presses, lifting equipment, and heavy machinery. They are typically used as the outer casing or barrel of hydraulic cylinders, which house the piston and hydraulic fluid.

Hydraulic pillar tube is based on high-quality carbon structural steel, appropriately adding one or several alloying elements to improve the strength, toughness and hardenability of the steel. After this type of steel is made, it usually needs to undergo heat treatment such as quenching and tempering, chemical heat treatment, and surface quenching. Compared with high-quality carbon structural steel, it has good comprehensive mechanical properties.

Hydraulic pillar pipes are manufactured according to international and industry standards to ensure quality and performance. Common standards include:

DIN 2391: German standard for precision seamless steel tubes.

ASTM A519: Standard specification for seamless carbon and alloy steel mechanical tubing.

EN 10305-1: European standard for precision seamless steel tubes for hydraulic and pneumatic systems.

JIS G3445: Japanese standard for mechanical structural carbon steel tubes.

Hydraulic pillar pipes are typically manufactured using the following processes:

Seamless Pipe Production: Hot rolling or cold drawing processes are used to produce seamless pipes with uniform wall thickness and high strength.

Heat Treatment: Pipes are heat-treated (e.g., quenching and tempering) to enhance their mechanical properties, such as hardness and toughness.

Machining: The inner and outer surfaces are precision-machined to achieve smooth finishes and tight tolerances.

Surface Treatment: Coatings or treatments (e.g., chrome plating, phosphating) may be applied to improve corrosion resistance and reduce friction.

EN

EN