What is the role of steel flanges?

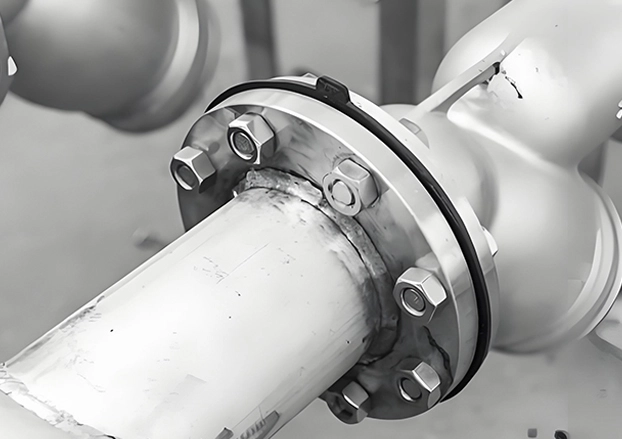

Steel flanges are mainly used for pipeline connections. Bolts are used to tightly connect two flanges, and gaskets are used to achieve sealing to ensure the sealing and stability of the pipeline system. It has the characteristics of strong structure, pressure resistance, corrosion resistance, and excellent sealing performance. It is widely used in industries such as petroleum, chemical industry, municipal water supply, and sewage treatment. Steel flanges have various connection methods, including threaded connection, welding connection, and socket connection. They are suitable for pipeline systems under different pressure and temperature conditions and are an indispensable and important component in pipeline connections.

What are the connection methods of steel flanges?

There are three main connection methods for steel flanges: threaded connection, welding connection and socket connection. For bulk procurement needs, flange wholesale channels offer comprehensive coverage of flanges with these three connection types, meeting the batch demand of industrial projects.

Threaded connection is through the thread on the flange, suitable for small-diameter, low-pressure pipelines, easy installation and low cost. Welded connection uses butt welds to weld the flange and the pipeline together. It is suitable for high-pressure and large-diameter pipelines. It has high connection strength and good sealing, but the welding process requirements are high. As a global hub for flange production and supply, flange china provides high-quality products matching these technical characteristics, with strict quality control for each connection type.

Socket connection is to insert the pipeline into the socket of the flange, and then connect it by welding or other fixing methods. It is suitable for small and medium-diameter pipelines, easy to disassemble and maintain, and the socket has a reinforcing effect. Many industrial clients prefer to cooperate with a professional flange manufacturer in china to customize flanges with targeted connection methods, ensuring perfect adaptation to their specific pipeline systems.

EN

EN