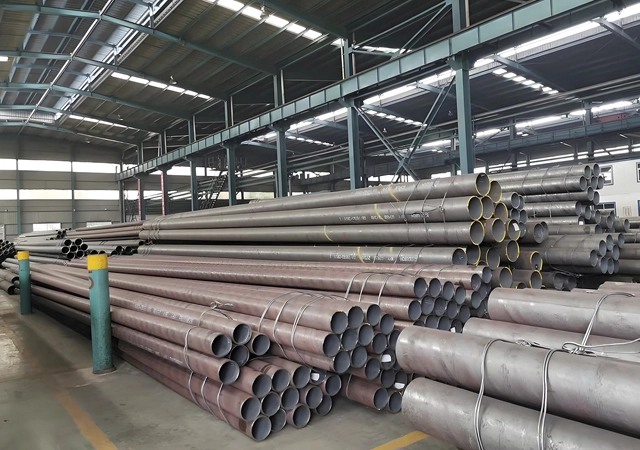

Seamless carbon steel pipe is a steel pipe without welds that is manufactured by hot rolling or cold drawing. It is mainly made of carbon steel with a carbon content usually between 0.06% and 1.5%, and may contain a small amount of manganese, silicon and other elements. Its manufacturing process includes hot rolling (suitable for large diameter, thick wall pipes) and cold drawing (suitable for small diameter, thin wall pipes with higher precision). The seamless structure gives it high strength, good pressure resistance and corrosion resistance, and can withstand high pressure and heavy load environments. Seamless carbon steel pipes are widely used in the fields of petroleum, natural gas, chemical industry, machinery manufacturing, etc., for conveying fluids (such as oil, gas, water) or as mechanical parts and structural components. Its advantages include seamlessness, high reliability and wide applicability, and it is an indispensable and important material in the industrial field—this also applies to seamless carbon steel tube and carbon seamless pipe.

The production process of carbon steel seamless pipe, a core product of professional carbon steel seamless pipe manufacturer and trusted seamless carbon steel pipe supplier, mainly includes hot rolling, cold drawing, extrusion and cold rolling. The hot rolling method is suitable for producing large diameter and thick wall pipes by heating the steel billet, perforating, rolling and sizing, and this process is also applied to the production of seamless carbon steel tube. The cold drawing method is suitable for small diameter and thin wall pipes with high precision by drawing through a die at room temperature, which is a key process for manufacturing carbon seamless pipe. The extrusion method is formed by an extruder and is suitable for high alloy steel and special shape pipes. The cold rolling method is cold rolled by a rolling mill and is suitable for high precision and high quality steel pipes. Each process is selected according to demand and is widely used in petroleum, chemical industry, machinery and other fields.

Carbon steel seamless pipes are widely used in many industrial fields due to their high strength, pressure resistance and corrosion resistance. The following are its main applications:

1. Oil and gas industry

Oil well pipes: used for drilling, oil production and oil and gas transportation.

Transportation pipelines: used for long-distance transportation of oil and natural gas.

2. Chemical industry

Chemical equipment: used to manufacture reactors, heat exchangers, separators and other equipment.

Transportation pipelines: used to transport corrosive media such as acids and alkalis.

3. Power industry

4. Machinery manufacturing industry

Structural parts: used to manufacture frames, shaft parts, etc. of mechanical equipment.

Hydraulic cylinder barrels: used to manufacture cylinder barrels and piston rods of hydraulic systems.

5. Automobile manufacturing industry

6. Construction Industry

7. Shipbuilding Industry

Marine pipes: used to manufacture ship piping systems, such as fuel pipes, cooling water pipes, etc.

Structural parts: used to manufacture structural parts and support parts of the hull.

8. Aerospace Industry

9. Food and Pharmaceutical Industry

Sanitary pipes: used to transport media with high hygiene requirements such as food and medicine.

Equipment manufacturing: used to manufacture food and pharmaceutical equipment, such as reactors, storage tanks, etc.

EN

EN