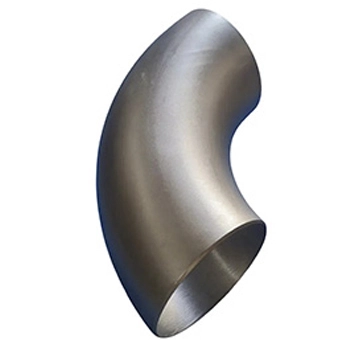

Carbon Steel Pipe Fittings Elbow could be a most common sort of CS fitting utilized to connect pipe or tubing to permit a alter of direction, more often than not a 90° or 45° angle, though 22.5 Degree Elbow Carbon Steel is additionally utilized in a piping framework, and it is a core product that carbon steel pipe fittings manufacturers focus on producing for industrial markets.

Carbon steel elbows are metal fittings that change the direction of the pipe on the carbon steel pipe. Connections are threaded and welded. Divided by angle, there are 45 ° and 90 ° 180 ° the three most commonly used, in addition to other engineering needs also include 60 ° and other abnormal angle elbow, with each of these elbows being a high-quality example of fitting carbon steel.

1. ASTM A234 WPB Standard

Application: This is the most common grade of carbon steel elbows used in piping systems.

2. ASTM A420 WPL6

Application: Used for cryogenic services.

3. ASTM A105 Standard

Application: Used for forged carbon steel fittings, including elbows, flanges, and other components.

4. ASTM A106 Grade B

Application: Used for seamless carbon steel pipe and fittings, including elbows.

5. API 5L Grade B

Application: Commonly used for pipes and fittings in the oil and gas industry.

6. ASTM A53 Grade B

Application: Used for seamless and welded steel pipe and fittings.

7. ASTM A350 LF2 Standard

Application: Used for cryogenic services, similar to A420 WPL6.

8. ASTM A694 F42, F52, F60, F65, F70

Application: High yield strength carbon steel fittings for high pressure applications, including elbows.

9. ASTM A860 WPHY 42, 52, 60, 65, 70

Application: High strength carbon steel fittings for high pressure applications, including elbows.

10. ASTM A691 Standard

Application: For high temperature and high pressure services.

Long Radius (LR) Elbow:

Description: The radius of curvature is 1.5 times the pipe diameter (R = 1.5D). This design provides a smoother flow transition, reducing turbulence and pressure drop.

Applications: Suitable for high-pressure and high-flow rate systems where minimizing pressure loss is crucial.

Short Radius (SR) Elbow:

Description: The radius of curvature is equal to the pipe diameter (R = D). This design is more compact and suitable for tight spaces.

Applications: Used in systems where space is limited and high-pressure conditions are not a primary concern.

Material Specifications: Carbon steel elbows must comply with industry standards such as ASTM A234, ASTM A105, and ASTM A420, which define the specific requirements for manufacturing, dimensions, and performance.

Surface Quality and Mechanical Properties: The surface quality and mechanical properties of the elbow are similar to those of the pipe. To facilitate welding, the elbow should be made from the same material as the pipe to be connected.

Connection Methods: Carbon steel elbows can be connected to pipes using welding, threaded connections, or other fitting methods.

1. Oil and Gas Industry: Used in pipelines for transporting oil, gas, and other hydrocarbons from extraction sites to refineries and distribution points.

2. Chemical Processing: Used in chemical plants for transporting various chemicals, acids, and solvents through processing equipment and piping systems.

3. Power Generation: Employed in power plants for conveying steam, water, and other fluids in boiler systems, cooling systems, and other process applications.

4. Construction and Infrastructure: Used in HVAC systems, water supply, and drainage systems in commercial and residential buildings, as well as for industrial construction projects.

5. Manufacturing: Utilized in various manufacturing processes for conveying fluids and gases within production equipment and facilities.

EN

EN