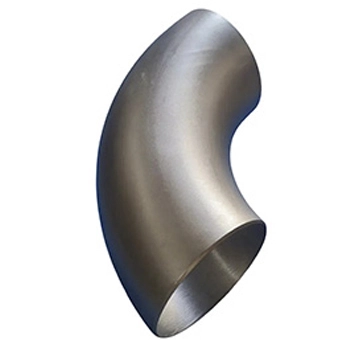

A butt welding elbow is a type of pipe fitting used to change the direction of fluid flow in a piping system. It is designed to be connected to pipes through butt welding, which involves aligning the pipe and elbow ends and then welding them together to create a strong, seamless joint. This method ensures a robust connection that can handle high pressure and temperature variations, making it ideal for critical applications.

Butt welding elbows are manufactured according to industry standards, such as:

ASME B16.9: Covers dimensions and tolerances for factory-made wrought butt-welding fittings.

ASME B16.28: Covers short radius elbows and returns.

MSS SP-43: Covers wrought stainless steel butt-welding fittings.

Butt welding elbows are available in various materials to suit different operational requirements:

Carbon Steel: Known for its high strength and durability, suitable for high-pressure and high-temperature environments.

Stainless Steel: Offers excellent corrosion resistance, making it ideal for applications in harsh environments.

Alloy Steel: Provides enhanced mechanical properties, including improved resistance to fatigue and stress, making it suitable for demanding applications.

1. Strength and Durability:The welded joint provides a strong, permanent connection that can withstand high pressure and temperature.

2. Leak-proof:Butt welding creates a seamless connection, reducing the risk of leaks.

3. Smooth Flow:The welded joint ensures a smooth inner surface, minimizing turbulence and pressure drop.

4. Versatility:Available in a wide range of materials, sizes, and angles to suit various applications.

5. Cost-effective:While the initial installation cost may be higher due to welding, the long-term reliability and low maintenance make it cost-effective.

1. Oil and Gas: Pipelines, refineries, and offshore platforms.

2. Power Generation: Steam lines, boilers, and turbines.

3. Chemical and Petrochemical: Corrosive and high-pressure systems.

4. Water Treatment: Pipelines and distribution systems.

5. Pharmaceutical: Hygienic and high-purity systems.

EN

EN