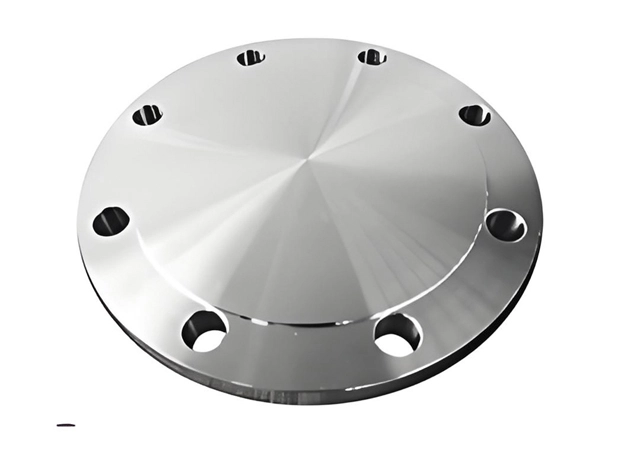

What is Blind Flange

A blind flange, also known as a blank flange, is a type of flange that has no central opening. It is a flat, circular plate with bolt holes around the perimeter, designed to be bolted onto the end of a pipe, valve, or other equipment in a piping system, and pipe blank flange is a direct synonym for this sealing component.

The main function of a blind flange is to completely seal off the end of a pipe or an opening in a vessel or equipment. It is used to isolate a section of the piping system for maintenance, repair, or when a particular branch or connection is not in use. For example, during the shutdown of a certain part of a chemical plant for inspection, blind flanges can be installed to prevent the leakage of fluids or gases and ensure the safety of the operation. In addition, it can also be used to change the flow direction or block certain passages in the piping system as needed. Among the diverse flange blind types, threaded blind flange is suitable for low-pressure pipelines due to its easy installation, while weld neck blind flange is preferred for high-pressure and high-temperature scenarios for its enhanced structural strength and sealing reliability.

Types of Blind Flange

Raised Face (RF) Blind Flange: Features a raised face around the sealing area to improve gasket compression.

Flat Face (FF) Blind Flange: Has a flat sealing surface, typically used with flat-faced flanges.

Ring-Type Joint (RTJ) Blind Flange: Designed with a groove to accommodate a metal ring gasket for high-pressure applications.

Threaded Blind Flange: Used to seal threaded pipe ends.

Weld Neck Blind Flange: Designed with a neck for welding to pipes or vessels.

Sizes and Pressure Ratings of Blind Flange

Sizes: Ranges from 1/2 inch (15 mm) to over 60 inches (1500 mm), depending on the standard.

Pressure Ratings:

ASME B16.5: Class 150, 300, 600, 900, 1500, 2500.

EN 1092-1: PN6, PN10, PN16, PN25, PN40.

Standards of Blind Flange

ASME B16.5:

Covers pipe flanges and flanged fittings for sizes 1/2 inch to 24 inches.

Includes pressure ratings from Class 150 to Class 2500.

Specifies dimensions, materials, and testing requirements for blind flanges.

ASME B16.47:

Covers large-diameter flanges for sizes 26 inches to 60 inches.

Divided into Series A (MSS SP-44) and Series B (API 605).

Includes blind flanges for high-pressure applications.

EN 1092-1:

European standard for flanges and their joints.

Covers blind flanges for sizes DN10 to DN4000.

Includes pressure ratings from PN6 to PN100.

JIS B2220:

Japanese standard for steel pipe flanges, including blind flanges.

Covers sizes 10A to 1500A and pressure ratings from 5K to 63K.

DIN 2527:

German standard for blind flanges.

Commonly used in European

Material Grade of Blind Flange

Carbon Steel: ASTM A105, ASTM A350 LF2.

Stainless Steel: ASTM A182 F304/304L, F316/316L, F321, F347.

Alloy Steel: ASTM A182 F11, F22, F5, F9.

Duplex and Super Duplex Steel: ASTM A182 F51, F53, F55.

Nickel Alloys: Monel, Inconel, Hastelloy.

Applications of Blind Flange

Industrial Piping

Used in factories to isolate sections of pipes during maintenance, like in chemical plants for safe repair. Many enterprises in this sector source high-quality sealing components from blind flange china for reliable performance in harsh industrial environments.

Power Generation

Applied in power plants to seal unused pipe ends, ensuring no leakage in steam or coolant systems.

Water and Wastewater

Employed in water treatment plants to block pipelines for inspection or when a line is decommissioned.

Oil and Gas

Utilized in oil refineries and gas pipelines to isolate areas during construction or for safety reasons. Global buyers often cooperate with professional blank flanges suppliers to obtain customized products that meet industry-specific pressure and corrosion resistance requirements.

Marine Industry

Installed on ships to seal off pipe openings in engine rooms or other areas as required.

EN

EN