What is Alloy Steel Flange

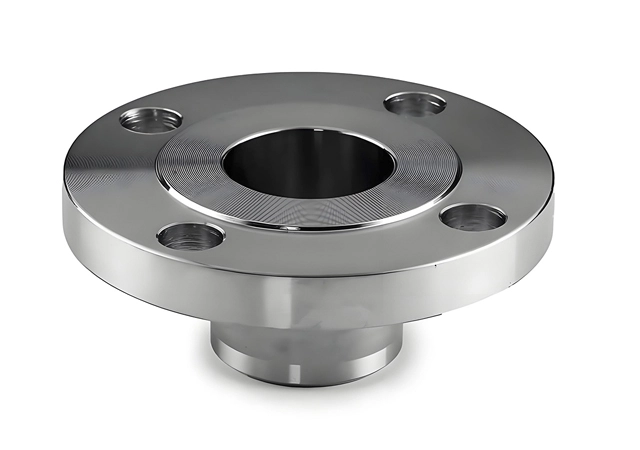

Alloy steel flanges are crucial connection components in piping systems, made from alloy steel materials that incorporate various alloying elements like chromium, nickel, and molybdenum. They usually have a circular shape with evenly distributed bolt holes for connecting pipes, valves and other equipment. For high-end industrial projects requiring consistent quality, collaborating with reputable alloy steel pipe flanges manufacturers ensures access to products that meet strict performance standards for high-pressure, high-temperature applications.

These flanges offer enhanced mechanical properties such as high strength, excellent toughness and good heat resistance compared to ordinary steel flanges. They can withstand high pressure, high temperature and corrosive media, ensuring the reliability and stability of the piping system.

Alloy steel flanges Widely used in petrochemical, power, aerospace and other high - end industrial fields, alloy steel flanges play a vital role in ensuring the safe operation of complex piping systems.

Types of Alloy Steel Flange

| Type of Flange | Features | Typical Applications |

| Weld Neck Flange | Long tapered hub, welded to the pipe, excellent for high-pressure systems. | High-pressure pipelines, oil and gas, petrochemical. |

| Slip-On Flange | Slides over the pipe and welded, easy to install, cost-effective. | Low-pressure systems, water treatment, HVAC. |

| Socket Weld Flange | Socket for pipe insertion, fillet welded, ideal for small-diameter pipes. | Small-diameter high-pressure systems, chemical plants. |

| Blind Flange | Used to seal pipe ends, no bore, prevents flow. | Pipeline testing, vessel closures, maintenance. |

| Threaded Flange | Internal threads for pipe connection, no welding required. | Low-pressure systems, air, water, and gas lines. |

| Lap Joint Flange | Used with a stub end, allows for easy alignment and disassembly. | Systems requiring frequent dismantling, food industry. |

| Spectacle Blind Flange | Combines a blind flange and a spacer, used to isolate pipeline sections. | Pipeline isolation, maintenance, and safety. |

| Orifice Flange | Designed for orifice meters to measure flow rates. | Flow measurement in oil, gas, and water systems. |

| Flat Face Flange | Flat sealing surface, used with flat gaskets. | Low-pressure systems, cast iron equipment. |

| Raised Face Flange | Raised sealing surface, used with soft gaskets. | General-purpose applications, high-pressure systems. |

| Ring-Type Joint (RTJ) Flange | Uses a metal ring gasket for high-pressure and high-temperature sealing. | High-pressure and high-temperature systems, oil and gas. |

Advantages of Alloy Steel Flange

High Strength: Alloy steel flanges can withstand high pressure and mechanical stress.

Temperature Resistance: Suitable for high-temperature applications, such as power plants and refineries.

Corrosion Resistance: Certain alloy grades (e.g., chromium-molybdenum) offer improved resistance to oxidation and corrosion.

Durability: Long service life even in harsh environments.

Versatility: Can be used in a wide range of industries and applications.

Standards of Alloy Steel Flange

ASME/ANSI B16.5: Covers dimensions, pressure ratings, and tolerances for pipe flanges and flanged fittings.

ASME/ANSI B16.47: Standard for large-diameter flanges.

ASTM A182: Standard specification for forged or rolled alloy and stainless steel pipe flanges.

ASTM A234: Standard specification for alloy steel fittings.

DIN EN 1092-1: European standard for flanges.

JIS B2220: Japanese industrial standard for steel pipe flanges.

ISO 7005: International standard for flanges.

Material Grade of Alloy Steel Flange

A182 F5/F9/F11/F22/F91: Forged alloy steel grades suitable for high-temperature service.

A387 Gr.5/Gr.9/Gr.11/Gr.22/Gr.91: Pressure vessel plates used for manufacturing flanges in demanding environments.

A234 WP5/WP9/WP11/WP22/WP91: Wrought alloy steel grades for fittings, including flanges.

A335 P5/P9/P11/P22/P91: High-temperature and high-pressure grades used in power plants and petrochemical industries.

Connection of Alloy Steel Flange

Bolting: Flanges are joined together with bolts and gaskets to create a tight seal.

Welding: Flanges like weld neck, slip-on, and socket weld are welded to the pipe for a permanent connection.

Threading: Threaded flanges are screwed onto the pipe without welding.

Applications of Alloy Steel Flange

Power Generation: For sealing pipes in boilers, turbines, and steam lines.

Oil and Gas: Used in pipelines, refineries, and offshore platforms.

Petrochemical: Suitable for handling corrosive chemicals and high-pressure systems.

Chemical Processing: Resistant to corrosive substances and high temperatures.

Aerospace: Used in high-stress and high-temperature environments.

Heavy Machinery: For hydraulic and pneumatic systems.

Construction: In structural and industrial piping systems.

EN

EN