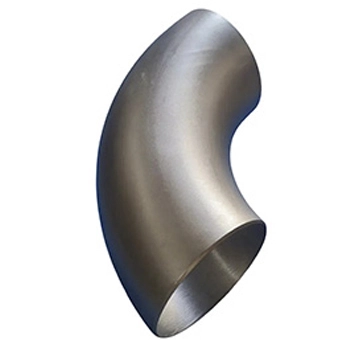

A 45-degree elbow is a type of pipe fitting used to change the direction of flow in a piping system by 45 degrees. It is commonly used when a less abrupt change in direction is required compared to a 90-degree elbow.

The 45-degree elbow allows for a smoother transition in the flow path, reducing pressure drop and turbulence, which makes it ideal for applications where fluid efficiency is critical.

Angle:Changes the direction of flow by 45 degrees.

Connection Types:Available in various connection types, including threaded, socket weld, butt weld, and flanged.

Materials:Made from materials like carbon steel, stainless steel, or copper, depending on the application.

Size:Available in a wide range of sizes, from small diameters (e.g., 1/2 inch) to large diameters (e.g., 48 inches or more).

Radius:Comes in two main types based on the curvature:

Long Radius (LR) Elbow: Has a larger curve, resulting in less pressure drop and smoother flow.

Short Radius (SR) Elbow: Has a tighter curve, suitable for tight spaces but may cause higher pressure drop.

Threaded 45-Degree Elbow:

Has threaded ends for screwing onto pipes.

Commonly used in low-pressure systems like plumbing.

Socket Weld 45-Degree Elbow:

Pipes are inserted into the fitting and welded for a strong connection.

Used in high-pressure systems.

Butt Weld 45-Degree Elbow:

Pipes and fittings are welded together end-to-end.

Ideal for high-pressure and high-temperature applications.

Flanged 45-Degree Elbow:

Has flanged ends for bolted connections.

Used in systems requiring frequent disassembly.

Long Radius (LR) 45-Degree Elbow:

The centerline radius is 1.5 times the pipe diameter.

Provides smoother flow and less pressure drop.

Short Radius (SR) 45-Degree Elbow:

The centerline radius is equal to the pipe diameter.

Suitable for tight spaces but may cause higher turbulence.

1. Smoother Flow:Provides a gentler change in direction, reducing pressure drop and turbulence compared to 90-degree elbows.

2. Space Optimization:Allows pipes to make gradual turns, saving space in piping systems.

3. Versatility:Available in various materials, sizes, and connection types to suit different applications.

4. Durability:Made from robust materials to withstand high pressure, temperature, and corrosion.

Space Requirements:Long-radius elbows require more space for installation.

Cost:Specialty materials (e.g., stainless steel) or larger sizes can be expensive.

EN

EN